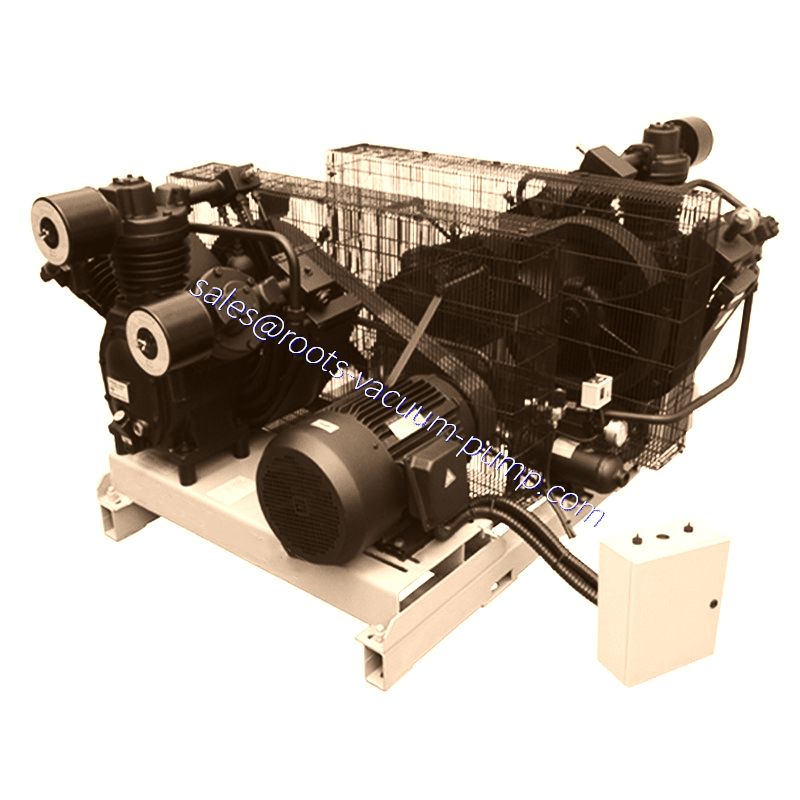

LUFTKOMPRESSOR FÜR EINBLASMASCHINEN

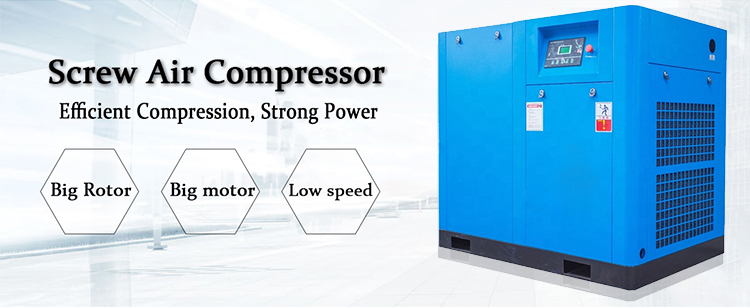

Blowing machine air compressor

1. Product features

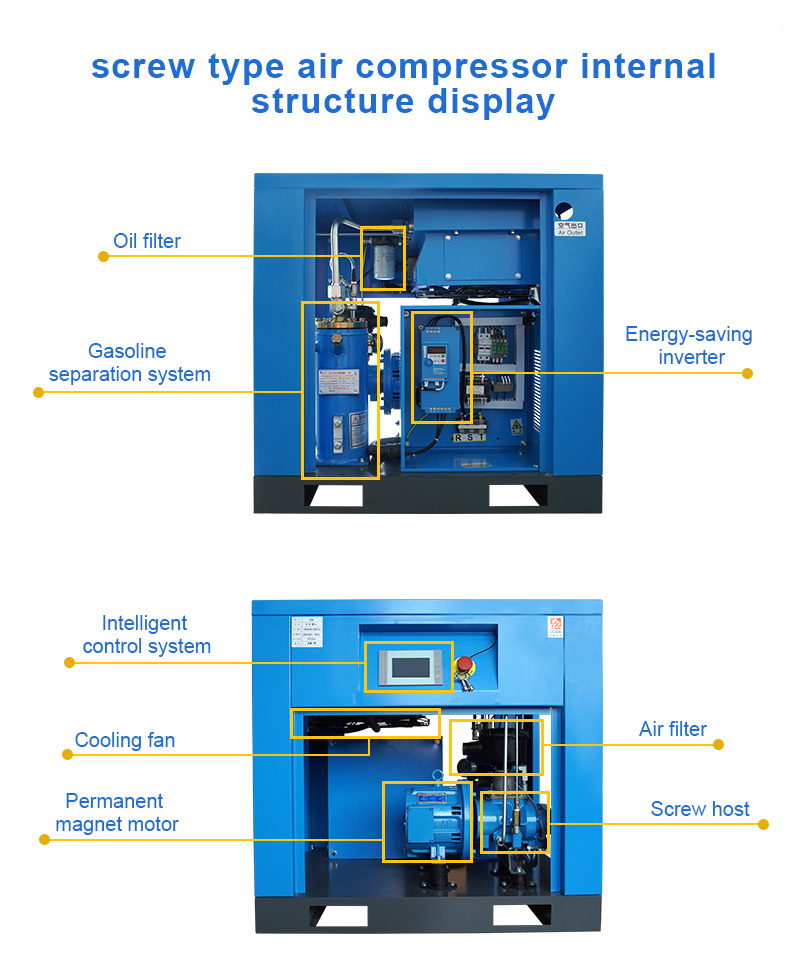

1. No shaft seal design, the main engine never oil leakage

Sinmyn’s unique patent technology, so that the main engine has no mechanical seal and no rubber sealing body, completely eliminate the leakage problem caused by the main engine seal, so that the main engine will never leak oil.

2. Power consumption, gas production at the same power is more than 15% larger than that of ordinary air compressor

AGKNX air compressor can save more than 25% of electricity for you, with CMN37G air compressor used 24 hours a day, 365 days a year, according to 1 yuan/KWH calculation: 37kW×24 hours ×365 days ×25%=80808 KWH electricity.

3 low oil content, compressed air oil content is very little

AGKNX‘s outstanding technical advantages, up to 95% volume efficiency can be used to achieve the sealing effect with a low amount of oil injection, combined with the unique design of oil and gas separation barrel, oil core processing burden is very light, so that the air oil content is minimal, oil core life is long.

4. High temperature resistance, can work continuously

Because the volume efficiency of the main engine is as high as 95%, that is to say, the leakage gas is only 5%, so the loss is very little, that is, the heat of the unit is very little, and the operating temperature is about 80℃ in the general environment. Design requirements can be 24 hours a day, 365 days a year continuous uninterrupted work.

5. Simple design structure

Series two main engine, simple structure, less power loss, high efficiency. The machine occupies less volume, convenient installation and simple maintenance.

6. AGKNX has mastered the core technology

Exhaust pressure from 0.4MPa to 4.0MPa, exhaust volume from 1 cubic to 43 cubic. Medium and high pressure screw air compressor is known as the pearl in the field of air compressor, xin Maien is the only domestic screw air compressor manufacturing enterprise that can produce pressure above 4.0mpa.

Superior electronic control operating system

By using the intelligent microcomputer control system, the unit with a powerful fault diagnosis and protective function which can work last for 24 hours without watch. If the unit happens to have faults, the system will respond appropriately according to the situations to inform people to replace parts and make the necessary maintenance in time. The operation is very simple, and the unit will change into automatic operation state immediately if people turn on switch.

Economic operation cost

The system uses a 0 ~ 100% displacement of stepless adjustment. The displacement reduces when gas consumption decrease, and the motor current also reduces simultaneously; air compressor runs empty when not using gas, and automatically stops when it runs empty for a long time. When the gas consumption increases, it will recover. It is the best energy saving system.

Good environmental adaptability

Extraordinary cooling system is especially suitable for the high-temperature, high humidity environment in Asia. With the excellent vibration isolation technology and noise reduction measures, the installation of AIVYTER screw air compressors does not need the specialized foundation. You can settle your air compressor only by leaving a minimal ventilation and maintenance space.

Technical Data of Direct Drive Electric Motor Screw Air Compressors

Superior electronic control operating system

By using the intelligent microcomputer control system, the unit with a powerful fault diagnosis and protective function which can work last for 24 hours without watch. If the unit happens to have faults, the system will respond appropriately according to the situations to inform people to replace parts and make the necessary maintenance in time. The operation is very simple, and the unit will change into automatic operation state immediately if people turn on switch.

Economic operation cost

The system uses a 0 ~ 100% displacement of stepless adjustment. The displacement reduces when gas consumption decrease, and the motor current also reduces simultaneously; air compressor runs empty when not using gas, and automatically stops when it runs empty for a long time. When the gas consumption increases, it will recover. It is the best energy saving system.

Good environmental adaptability

Extraordinary cooling system is especially suitable for the high-temperature, high humidity environment in Asia. With the excellent vibration isolation technology and noise reduction measures, the installation of AIVYTER screw air compressors does not need the specialized foundation. You can settle your air compressor only by leaving a minimal ventilation and maintenance space.

Technical Data of Direct Drive Electric Motor Screw Air Compressors

| Modell | Motorleistung | Arbeitsdruck | Capacity | Lubricating oil quantity (L) |

Noise (dB) |

Dimension(mm) | Net Weight | Air Outlet Pipe Diameter | ||||

| kw/hp | Psi | bar | Cfm | m3/min | L | W | H | KGS | ||||

| SGD08 | 7.5/10 | 102 | 7 | 42.4 | 1.2 | 10 | 66±2 | 900 | 670 | 845 | 220 | 1/2’’ |

| 116 | 8 | 38.8 | 1.1 | |||||||||

| 145 | 10 | 33.5 | 0.95 | |||||||||

| 174 | 12 | 28.3 | 0.8 | |||||||||

| SGD11 | 11/15 | 102 | 7 | 58.3 | 1.65 | 18 | 68±2 | 1000 | 750 | 1015 | 300 | 3/4’’ |

| 116 | 8 | 53 | 1.5 | |||||||||

| 145 | 10 | 45.9 | 1.3 | |||||||||

| 174 | 12 | 38.8 | 1.1 | |||||||||

| SGD15 | 15/20 | 102 | 7 | 88.3 | 2.5 | 18 | 68±2 | 1000 | 750 | 1015 | 300 | 3/4’’ |

| 116 | 8 | 81.2 | 2.3 | |||||||||

| 145 | 10 | 74.2 | 2.1 | |||||||||

| 174 | 12 | 67.1 | 1.9 | |||||||||

| SGD18 | 18.5/25 | 102 | 7 | 113 | 3.2 | 18 | 68±2 | 1130 | 850 | 1175 | 480 | 1’’ |

| 116 | 8 | 105.9 | 3 | |||||||||

| 145 | 10 | 95.3 | 2.7 | |||||||||

| 174 | 12 | 84.7 | 2.4 | |||||||||

| SGD22 | 22/30 | 100 | 7 | 134.2 | 3.8 | 18 | 68±2 | 1130 | 850 | 1175 | 480 | 1’’ |

| 116 | 8 | 127.1 | 3.6 | |||||||||

| 145 | 10 | 113 | 3.2 | |||||||||

| 174 | 12 | 95.3 | 2.7 | |||||||||

| SGD30 | 30/40 | 102 | 7 | 187.1 | 5.3 | 18 | 68±2 | 1130 | 850 | 1175 | 480 | 1’’ |

| 116 | 8 | 176.6 | 5 | |||||||||

| 145 | 10 | 158.9 | 4.5 | |||||||||

| 174 | 12 | 141.2 | 4 | |||||||||

| SGD37 | 37/50 | 102 | 7 | 240.1 | 6.8 | 30 | 68±2 | 1250 | 1000 | 1335 | 500 | 11/2″ |

| 116 | 8 | 218.9 | 6.2 | |||||||||

| 145 | 10 | 197.7 | 5.6 | |||||||||

| 174 | 12 | 176.6 | 5 | |||||||||

| SGD45 | 45/60 | 102 | 7 | 261.3 | 7.4 | 30 | 72±2 | 1250 | 1000 | 1335 | 500 | 11/2″ |

| 116 | 8 | 247.2 | 7 | |||||||||

| 145 | 10 | 218.9 | 6.2 | |||||||||

| 174 | 12 | 197.7 | 5.6 | |||||||||

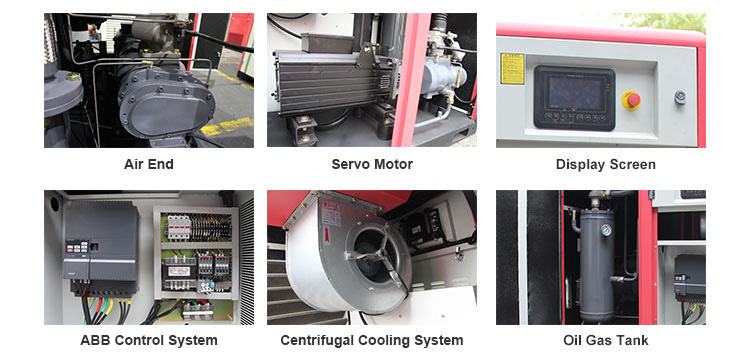

Description

The servo variable frequency compressor is a competitive product among the high-grade machines, the quality of air end of servo variable frequency compressor is excellent. The advanced molded lines ensure the minimum specific power. It is designed in the FEM strength analysis, to ensure the stability and reliability of each part, and to realize long term operation with no faults, low noise and long life.

Advantages

- Rotor:Rotors are asymmetric in profile, backed up by ball bearings and roller bearings. Operates at a low speed, thereby low in abrasion and maintenance expenses, air end is long service life. Helical gears can produce axial force to kill some acting force, which reduces the load of the bearing of air end.

- Control panel:

Intelligent microcomputer-based control technology can monitor and control in all aspects the complete machine following your instructions, remote control realizes unattended operation, and the user-friendly human-machine interface displays instructions and parameters in written form also, it can function to self diagnose faults, give warning and automatically regulate the capacity.

- Oil filter:Rotary filters are applied to completely remove the impurities in the lubricating oil, easy to replace and free of oil impregnate.

- Cooler:It is designed for low temperature difference to increase heat exchange area, and ideal to be applied to high-humidity operating environment.

- Excellent quality of motors:Compared to normal motors, Servo motors have smaller dimensions and more excellent energy saving.It will exert incomparable energy saving effect than normal inductive motor when installed with the special frequency convectors.

- The host machine of compressor is of high efficiency and long life:The quality of host machine of permanent magnet synchronizing variable frequency compressor is excellent. The advanced molded lines ensure the minimum specific power.It is designed in the FEM strength analysis.to ensure the stability and reliable of each part,and to realize long term operation with no faults,low noise and long life.

| Servo Permanent Magnet VSD Compressor Technical Parameters (20HP/15kw ~ 200HP/160kw) |

||||||||||||

| Modell | Arbeitsdruck | Air Delivery | Motorleistung | Dimension(mm) | Gewicht (kg) |

Output pipe Diameter | ||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||

| ERC-20SA | 116 | 8 | 33.9 – 84.7 | 0.96 – 2.4 | 15/20 | 1200 | 850 | 1280 | 665 | 1″ | ||

| 145 | 10 | 31.1 – 77.7 | 0.88 – 2.2 | |||||||||

| 181 | 12.5 | 29.7 – 74.2 | 0.84 – 2.1 | |||||||||

| ERC-25SA | 116 | 8 | 42.4 – 102.4 | 1.2 – 2.9 | 18.5/25 | 1200 | 850 | 1280 | 665 | 1″ | ||

| 145 | 10 | 35.3 – 95.3 | 1.1 – 2.7 | |||||||||

| 181 | 12.5 | 32.5 – 81.2 | 0.9 – 2.3 | |||||||||

| ERC-30SA/ ERC-30SW |

116 | 8 | 50.8 – 121.7 | 1.4 – 3.6 | 22/30 | 1200 | 850 | 1280 | 665 | 1″ | ||

| 145 | 10 | 45.2 – 113.0 | 1.3 – 3.2 | |||||||||

| 181 | 12.5 | 39.5 – 88.3 | 1.1 – 2.8 | |||||||||

| ERC-40SA/ ERC-40SW |

116 | 8 | 70.6 – 176.6 | 2.0 – 5.0 | 30/40 | 1450 | 1000 | 1465 | 1110 | 11/4″ | ||

| 145 | 10 | 60.7 – 151.8 | 1.7 – 4.3 | |||||||||

| 181 | 12.5 | 50.8 – 127.1 | 1.4 – 3.6 | |||||||||

| ERC-50SA/ ERC-50SW |

116 | 8 | 87.6 – 218.9 | 2.5 – 6.2 | 37/50 | 1450 | 1000 | 1465 | 1110 | 11/4″ | ||

| 145 | 10 | 80.5 – 201.3 | 2.3 – 5.7 | |||||||||

| 181 | 12.5 | 65.0 – 162.4 | 1.8 – 4.6 | |||||||||

| ERC-60SA/ ERC-60SW |

116 | 8 | 108.8 – 271.9 | 3.1 – 7.7 | 45/60 | 1450 | 1000 | 1465 | 1750 | 2″ | ||

| 145 | 10 | 94.6 – 243.6 | 2.7 – 6.7 | |||||||||

| 181 | 12.5 | 84.7 – 211.9 | 2.4 – 6.0 | |||||||||

| ERC-75SA/ ERC-75SW |

116 | 8 | 138.4 – 346.0 | 3.9 – 9.8 | 55/75 | 2100 | 1250 | 1700 | 1750 | 2″ | ||

| 145 | 10 | 122.9 – 307.2 | 3.5 – 8.7 | |||||||||

| 181 | 12.5 | 103.1 – 257.8 | 2.9 – 7.3 | |||||||||

| ERC-100SA/ ERC-100SW |

116 | 8 | 183.6 – 459.0 | 5.2 – 13.0 | 75/100 | 2100 | 1250 | 1700 | 1840 | 2″ | ||

| 145 | 10 | 159.6 – 399.0 | 4.5 – 11.3 | |||||||||

| 181 | 12.5 | 142.7 – 356.6 | 4.0 – 10.1 | |||||||||

| ERC-120SA/ ERC-120SW |

116 | 8 | 217.5 – 543.8 | 6.2 – 15.4 | 90/120 | 2170 | 1320 | 1750 | 2030 | 2″ | ||

| 145 | 10 | 186.4 – 466.1 | 5.3 – 13.2 | |||||||||

| 181 | 12.5 | 158.2 – 395.5 | 4.5 – 11.2 | |||||||||

| ERC-150SA/ ERC-150SW |

116 | 8 | 275.4 – 688.5 | 7.8 – 19.5 | 110/150 | 2545 | 1500 | 1900 | 3100 | DN65 | ||

| 145 | 10 | 233.0 – 582.6 | 6.6 – 16.5 | |||||||||

| 181 | 12.5 | 193.5 – 483.7 | 5.5 – 13.7 | |||||||||

| ERC-175SA/ ERC-175SW |

116 | 8 | 324.9 – 812.1 | 9.2 – 23 | 132/175 | 2545 | 1500 | 1900 | 3400 | DN65 | ||

| 145 | 10 | 282.5 – 706.2 | 8.0 – 20.0 | |||||||||

| 181 | 12.5 | 218.9 – 547.3 | 6.2 – 15.5 | |||||||||

| ERC-200SA/ ERC-200SW |

116 | 8 | 367.2 – 918.1 | 10.4 – 26 | 160/200 | 2545 | 1500 | 1900 | 3400 | DN65 | ||

| 145 | 10 | 331.9 – 829.8 | 9.4 – 23.5 | |||||||||

| 181 | 12.5 | 275.4 – 688.5 | 7.8 – 19.5 | |||||||||

| Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ 220V/3PH/50HZ/60HZ 400V/3PH/50HZ/60HZ 440V/3PH/50HZ/60HZ 415V/3PH/50HZ/60HZ 230V/3PH/50HZ/60HZ dual voltage is also ok |

||||||||||||

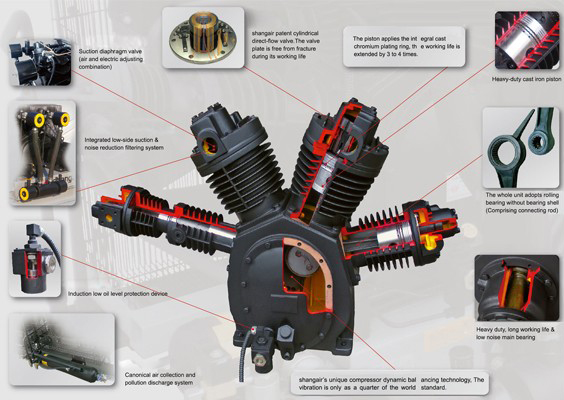

Low exhaust temperature, vibration, low noise, low fuel consumption.

Much more efficient and more reliable

KB series air compressors are widely used in pneumatic clamping, pneumatic tools, tire inflation, blowing craft,

painting, sand blasting, jet components and other places that need compressed air!

1.Strongly power driven and big air end with design, the air compressor owns bigger and heavier main parts than other products in the same trade with better selection and sufficient using of material especially with main fittings, In addition ,it is more suitable to be applied in the continuous operation under heavy load for long working time with higher reliability and longer lifespan.

2.Special designed is made in heat emission and air flow , which leads to low air-output temperature and low possibility of carbon deposite .

3.The piston ring imported from Japan is introduced in designing pistol ring , which is durable and sealable.

4.Crankshaft undergoes high-frequency hardening ,which enables it especially abrasion-proof.

5.Some relevant working unites are received precision balance, which makes it more stable with lower noise.

6.The core of air filter is made of imported filter paper, which acts well in filtering and silencing of noise.

7.Special oil separation construction is built insite the frontend jacket , so no oil vents form the breather valve , which ensures low oil consumption and cleanness of machine body.

air end three – year warranty

Leak – free design of environmental protection, oil consumption low

OEM,ODM service

have stock compressor

CE,ISO9001,GC,ASME certificates

KB-15 30bar High Pressure Mini Portable Air compressor for Sand Blasting and PET bottle blowing machine

Industrial Medium-Pressure Compressors (KB series)

KB series air compressor widely used in pneumatic lock, pneumatic tool,tire inflation,blowing process,spray paint,sand blasting and fluidic element.

Capacity :0.7-4.8m3/m

Pressure:25-40bar

ATTENTION:WE CAN CHANGE THE ELECTRIC POWER AS PER YOUR REQUIREMENT .

Featured with a low rotational speed, heavy-duty performance, and continuous operation, our reciprocating piston air compressors of the medium-pressure series demonstrates such advantages as low displacement temperature, little vibration, low noise, and low oil consumption.

Despite low malfunction rates and high reliability, the entire compressor is rationally structured with a simple system that is under reliable control, which ensures stable performance.

These compressors comprise a relatively complete product series, including those with mobile air storage tanks, fixed types, individual unit, and even a compressor unit with a relatively larger displacement.

To better accommodate bottle-blowing machines, we design and develop an integrated compressor unit, including a medium-pressure compressor, a low-pressure compressor for compound die, an air storage tank, a filter, and an air dryer.

To ensure a powerful design for compressor heads, sufficient first-rate materials are utilized. In addition, the design of major components is also reinforced, with the size and weight of the compressor head larger than products of other manufacturers, as well as a better safety tolerance.

Designed with a low rotational speed, such compressors are particularly suitable for continuous operation under heavy loads during a lengthy timeframe, while maintaining a long service life with great reliability.

These compressors are designed with special heat dissipation and airflow control. The discharge temperature is low, carbon buildup is less likely, and the efficiency is high.

The design of a ring valve bank comprises Swedish stainless valve plates and Japanese specialized valve springs. In operation, the valve plates do not experience any bending motion, ensuring excellent valve performance and service life.

Riken piston ring is endurable for a long period without the addition of oil.

The frequently quenched bent axle is particularly wearable.

As precisely balanced, the motion components operate steadily with a very low noise level.

The air filter core is made of imported filter paper, which ensures excellent filtration and noise reduction. In addition, it features long-lasting durability.

The front end contains such special design features as an oil separation structure. The breather valve does not leak oil, ensuring low oil consumption and maintaining a clean main body.

The copper bell mouth for displacement has a reasonable expanded angle with protective cover, preventing fracture and air leakage.

Branded products are used for such compressors, including pressure switch, contactor, and thermal relay, ensuring reliable control and protection.

In terms of displacement control, four options are available for users, including pneumatic automated control, electric automated control, pneumatic and electric dual control (manual switch), intelligence control (the switch between pneumatic and electric controls is subject to air consumption), which satisfy users’ different requirements.

An intelligence controller may be added for those users who experience complicated air consumption.

For medium-pressure compressors that require a relatively higher-pressure ratio, we specifically design an intercooler with a powerful capacity to maintain a relatively lower displacement temperature.

30Bar Medium High Pressure Piston Air Compressor for PET Bottle Blowing Plant

Product Application

Mainly used as the air power source for your plastic blow molding machinery;

Also can be used for leakage detection test in exploration, sweeping lines, gas lift and other projects.

|

Modell

|

Air Capacity

(Nm3/min)

|

Discharge Pressure

(Mpa)

|

Motorleistung

(KW)

|

Running Speed

(r.p.m)

|

Gewicht

(KG)

|

|

2-09WM-1130

|

2.0

|

3.0

|

11*2

|

600

|

1050

|

|

2-09WM-1130H

|

2.4

|

3.0

|

11*2

|

630

|

1090

|

|

2-09WM-1530

|

2.4

|

3.0

|

15*2

|

670

|

1150

|

Why Choose Us ? ~ Do you know how much does an Air Compressor Cost in China?

1. Installation & adjustment

After the equipment are arrived at the customer’s site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians’ guidance. Costs of the staff are decided at last.

2. Training

1). We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users’technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

2). The buyer can send staff to our company for learning.

3. Quality assurance

1). We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.

2). We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.

3). We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

4). The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer’s factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

Q1: Are you a manufacturer or trading company?

A: We are professional manufacturer with big modern factory in Shanghai,China. Both OEM & ODM service can be accepted.

Q2: What’s your delivery time?

A: Generally 3 to 7 days, if urgently order, pls contact our sales in advance.

Q3: How long is your air compressor warranty?

A: One year for the whole machine and two years for screw air end, except consumble spare parts.

Q4: How long could your air compressor be used?

A: Generally, more than 10 years.

Q5: What’s payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc.

Also we could accept USD, RMB, Euro and other currency.

Q6: How about your customer service?

A: 24 hours on-line service available. 48hours problem sovled promise.

Q7: How about your after-sales service?

A: 1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.