Rotary vane pump

A rotary vane pump is an ingenious machine and in its most basic form, it is like any other type of air compressor. The pump works by creating suction in the pump chamber with an intake valve and exhaust valve that creates compression inside the device to suck up molecules like dust, dirt, and other particles that are near or in contact with it.

- Unique throughput selector allows pump to be optimised for high and low pressure applications

- Hardened shaft sleeve for reliability & durability

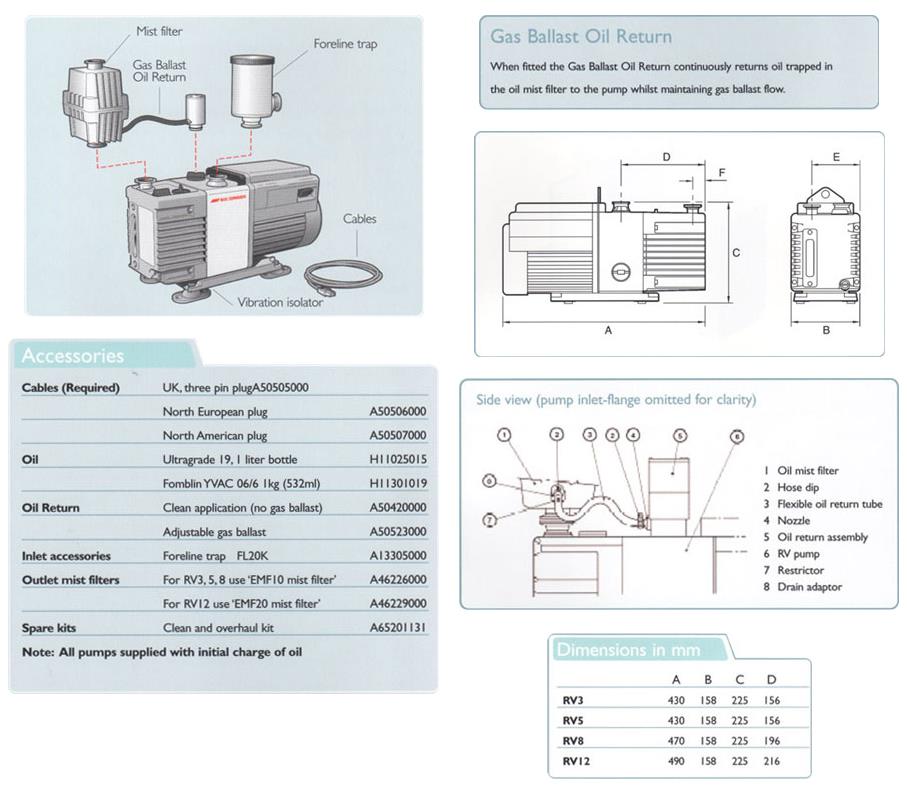

- Gas Ballast – highest vapour pumping rate in class! Use of Gas Ballast Oil Return strongly recommended

- Gas Ballast Oil Return unique accessory allows: Return of oil and gas ballast simultaneously 3 different settings Easy addition to existing mist filters

The pump operates in a circular motion and by spinning it creates pressure that forces the trapped fluid through the discharge pipe. The vanes attached inside have blades that open when it spins towards the discharge pipe; the fluid inside then rushes out of those same blades during spin back into the intake pipe while sucking more up from below ground level with each rotation. Due to the use of brute force, the pumps are also known as positive displacement.

As the name itself hints, the vane pumps have rectangular-shaped vane ascended into slots on a rotor that whirls inside the asymmetrical pump container. As the rotor starts working, the container induces the vanes to move to and fro out of the slots to touch the container walls and trap the fluid between the slot and rotor. The mechanism continues working until it’s forced and flushed out of the outlet portal.

COMPANY INTRODUCTION & EVER-POWER

Ever-power Vacuum Pump Group. is located in Wubei Town, which is known as the “Hometown of Pumps and Valves in China”. We-vacuum pump manufacturers and vacuum pump distributors-specialize in the production of vacuum pumps with extensive experience in this field. Through the dedication and hard work of our young team, our products enjoy a high reputation at home and abroad. Our main products include rotary vane vacuum pumps…

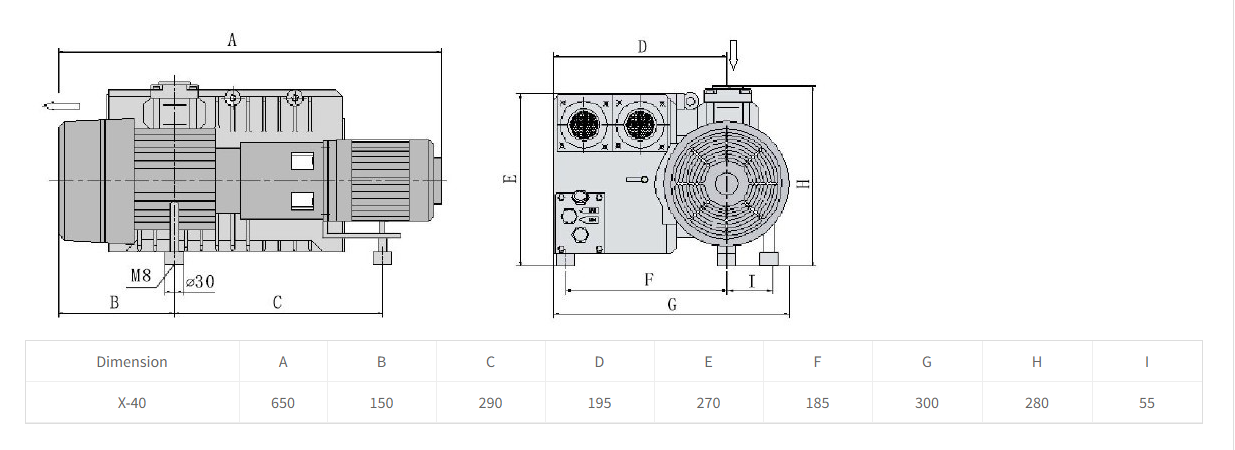

Single Stage Rotary Vane Vacuum Pump

Rotary vane vacuum pumps for the automotive industry

It can be used in the production and scientific research departments of metallurgy, machinery, electronics, chemical industry, light industry, petroleum, medicine and so on.

Long blade life, low noise, easy maintenance, can withstand high water vapor, long maintenance intervals

1. Low noise, low vibration, air cooling, convenient and easy to use.

2. It can still work well under high temperature environment and maintain a good pumping speed under low vacuum pressure.

3. The built-in filter element and filter can achieve a higher filtering effect, and the built-in one-way valve prevents the vacuum oil from returning.

4. Simple structure, small size, space saving, multi-functional concept, can be matched with customers’ special configuration, simple maintenance.

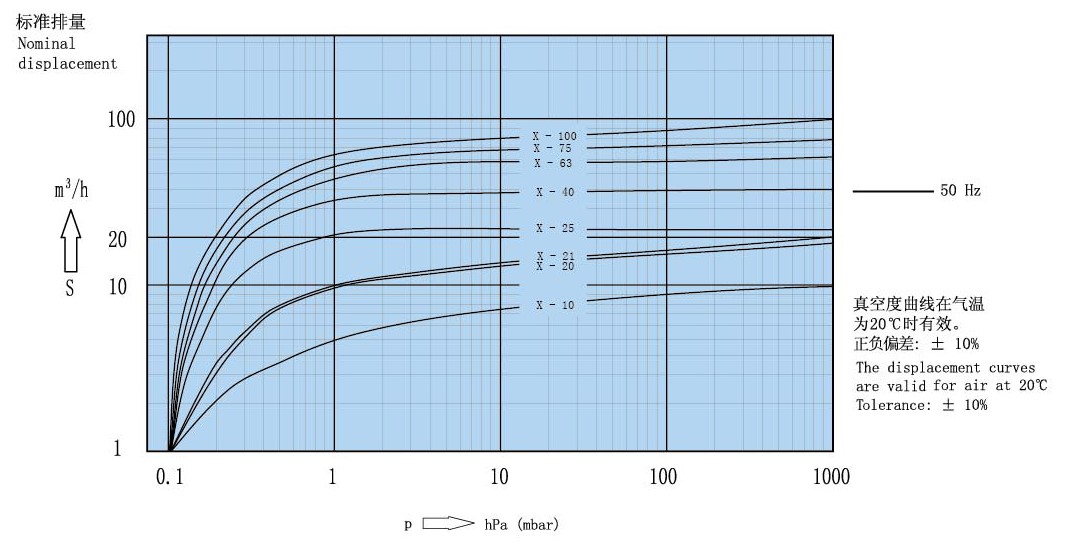

5. Adopt single-stage design, the ultimate vacuum can reach 0.1 mbar abs, and the flow can provide 20-750 m3 / hr (50Hz), 900m3 / hr (60Hz);

6. The blade is made of composite material, strong and durable.

7. Air-cooled design is adopted as standard, but water-cooling device can be added, which is suitable for use in environments with higher room temperature.

8. The built-in gas ballast valve can handle heavier humid air, and there is an efficient oil mist separator inside, so the installation process is very simple.

9. The motor adopts European IE2 high-efficiency motor, which saves electricity and travels far.

10. It can provide various vacuum systems for various occasions requiring central negative pressure, reliable and durable, suitable for rough and medium vacuum applications.

11. It can be used alone or as a backup pump for other high vacuum pumps or ultra-high vacuum pumps, and as a pre-pump for ultra-high vacuum pumps.

Experience precipitation

Focus on vacuum system for 16 years, rich industry experience, professional manufacturing technology

Half the price, twice the quality

Both price and quality can combine fish claws and bear paws. World-class performance is only half the price

Fine sanding

Exquisite and durable, every detail has been carefully polished, so the vacuum equipment is also artistic

Recognized by many famous companies

Years of quality has created a reputation and has been trusted by many well-known companies such as Huawei and Gree

Noise reduction processing

In order to be durable and easy to use, German technology has carried out noise reduction treatment, environmental protection and energy saving are more worry-free

General affairs

General affairs

From production, sales to maintenance, we provide a complete service process, so we can more easily meet customer needs

Rotary Vane Pump Systems

The combination of a chemical duty diaphragm pump with a rotary vane pump was developed to take advantage of the strong specifications of each type of pump.

The two-stage chemical duty diaphragm pump is able to withstand corrosive gasses and remove the resulting condensate prior to its absorption in the two-stage rotary vane pump oil by constantly distilling the oil during operation.

The rotary vane pump provides a much lower ultimate vacuum and will have a long life with the pump oil being free of contaminates. The result is a vacuum pump system with the vacuum capabilities of a rotary vane pump combined with the solvent and acid handling capabilities of a PTFE diaphragm pump.

In addition to the standard system models, Ever-Power offers further combination pump systems on request, including systems with different mains voltage and frequency.

Beside the rotary vane pump and the diaphragm pump, Chemvac vacuum systems consist of exhaust oil mist separator (AKD), separator bottle, oil box vacuum gauge, mains cable, plug, KF small flange connections, clamp and centering rings and Labovac 14 oil loading.

Applications: Vacuum manifold, Freeze drying (Lyophilisation), Industrial Applications

The mobile laboratory rotary vane pumps in china system has been specifically designed for use in chemistry laboratories. Its construction has intentionally been kept simple, compact and clearly arranged. The upstream cold traps enable even larger quantities of condensable vapors to be pumped without any additional pump load. The Dewar vessels protect the pump from chemical vapors. Moreover, the oil mist separator (AKD) captures any oil mist.

Applications: Vacuum oven, Industrial, Vacuum manifold, Concentrator

Roots system

The roots pump systems are complete, optimized and compact vacuum systems consisting of a roots pump and a two-stage rotary vane backing pump. Roots pump systems are well established in many fields of production and research where large pumping speeds are required at pressures in the rough and fine vacuum range. The roots blower is controlled via a frequency converter to allow ramp-up of roots blower and rotary vane pump at the same time.

Perks of our vane pump

Versatile design

The vane pump design is perfect for handling a range of low to medium viscosity clean fluids, including those at high temperatures and other liquids that can be found in your everyday life. The little metal-to-metal contact means you’ll never have trouble with the liquid drying out or becoming hard for it to pass through.

Low maintenance

The vane pump is designed to be low maintenance as the vanes are easily replaced. This means that these pumps require little time, and they also do not cost much money.

Besides, vanes can be easily removed by hand in just seconds when needed which also saves a lot of time.

Good suction capability

Due to the tight seal between the vanes, rotor, and pump casing, vane pumping benefits and offer good suction capabilities that make them ideal for tank stripping.

Can operate without fluid for short-term

When it comes to rotary vane pumps in china, they’re also a great option for those wishing their pump never needs to be turned off, as these pumps possess the ability to run without fluid entering the pump for a short while.

Achieve your goals

Company Concept

Company adhering to the management objective of quality first, prestige supreme.

Strong Technical Force

Strong technical force, superior to similar products in Japan and Germany, please refer to vacuum pump comparison for more detailed information. Advanced production and testing equipment, strict implementation of ISO9001 quality management system, products have obtained CE certification, and the ep series have passed US authoritative testing and certification

24/7 Customer Support

24×7 service support is one of the best services in the company. 24×7 service support providing quality services at anytime, anywhere in the world.

5 Tips to Make Your Rotary Vane Pumps Last Longer

1. Don’t restrict the exhaust pipe

Make sure that the exhaust pipe is not blocked by mechanical equipment or dirt accumulates in the exhaust pipe. Implementing regular and thorough maintenance procedures will help keep the production line open. In addition, please place the pump carefully so that the exhaust pipe has enough exhaust space.

2. Keep the pump cool

EVER-POWER rotary vane pumps are air-cooled. This means that you must place the pump in a well-ventilated area to prevent overheating and malfunction.

3. Use quality filters

If you have particles in your work space, you must have a filter of sufficient quality to prevent these particles from entering the pump system.

4. Use gas ballast

If you run the pump under normal atmospheric conditions, water vapor will almost always seep into the vacuum system. When steam enters, it can cause serious operational problems, such as preventing the pump from reaching the optimum pressure.

5. Eliminate oil mist

Oil mist or smoke in the exhaust port of the pump may be hazardous to health and cause wear and tear on the pump. To ensure safe operation, please choose a suitable oil mist eliminator for your pump.

Our range of products also includes:

- Rotary piston pump

- Air-cooled root vacuum pump

- Scroll compressor

- Screw compressor

- Rotary vane pump

- Liquid ring vacuum pump

- Oil-free compressor

- Oilless compressor

- Gebläse

- Water band vacuum pump

- Reciprocating vacuum pump

- Vacuum valve and others

So if your business requires this little dynamo then nothing can beat our products in the market. Using modern technologies and evolution our pumps are designed to meet all the requirements. Besides all, we believe in keeping with the quality to provide 100% customer satisfaction. So if you want to purchase your equipment from us then you can go on our website and check the inventory https://roots-vacuum-pump.com/vacuum-pumps/

For any other queries, you reach us via email [email protected]

Ready to get started?

Keep in touch or order products