AIR COMPRESSOR FOR LASER CUTTING MACHINE

air compressor for laser cutter | laser cutter air compressor | laser machine air compressor

Micro-oil 1.8MPa pressure permanent magnet variable frequency screw air compressor

Pressure 18 kg: laser cutting speed increased by 50%, smooth and no burrs.

Stable and reliable: It adopts the energy-saving main engine with large screw, low speed and double-acting opposing compression cavity, and adopts heavy-duty bearing: the equipment is more reliable and stable, and the performance of the whole machine is improved by more than 20%.

The equipment runs smoothly and has low noise: the double-acting opposed compression cavity energy-saving host has lower operating vibration and will not fall down even if you set up a coin. Quiet operation, can be installed on site, saving high pipeline fees.

Oil content≤2PPM: The same filter has better effect, ensuring that the laser head is not polluted and has a long service life.

There is also a 30 kg pressure laser cutting screw air compressor to choose from, allowing your laser cutting machine to release the maximum capacity.

A full set of professional laser cutting screw compressed air solutions let you rest assured! Make it go!

|

Power frequency (permanent magnet frequency conversion) screw air compressor CMNZG11APV-1.8MPa |

|

|

Exhaust pressure(MPa) |

1.8 |

|

Exhaust flow(m³/min) |

0.7 |

|

Supply air temperature(℃) |

Ambient temperature +15℃ |

|

Gas supply oil content |

≤2ppm |

|

cooling method |

Air cooling |

|

Delivery method |

Direct coupling |

|

Lubrication method |

Fuel injection |

|

Noise(dB(A)) |

62 |

|

Main motor power |

11kW |

|

Fan motor power |

150W |

|

Dimensions (mm) |

1100×680×1010 |

|

Weight (kg) |

390 |

|

Outlet size |

1″ |

|

Start method |

Star-delta start (frequency conversion start) |

The main benefit of rotary screw compressors is the energy efficiency. But this type of compressor has many other benefits.

* Low noise output

* No duty cycle

* Low oil-carryover (as little as 3 ppm) in oil lubricated machines

High efficient *Combined with direct driven arrangement for superior energy efficiency *Water seals and cools for ideal compression *Optimal compression processes with the water cooling Minimum service costs *Only air filter and water filter need maintenance *No lubricant costs *Fast and easy for minimal downtime High reliability *Simple and robust design * Low-speed direct drive, no high speed gears *Low operating temperatures, no special coatings High-quality air *Low air temperature, easy to dry and treat *No coating on routers that can contaminate or pollute the air *Class 0 air quality Environmental safety *Low noise level *Reduce energy consumption *No oil discharge to the environment

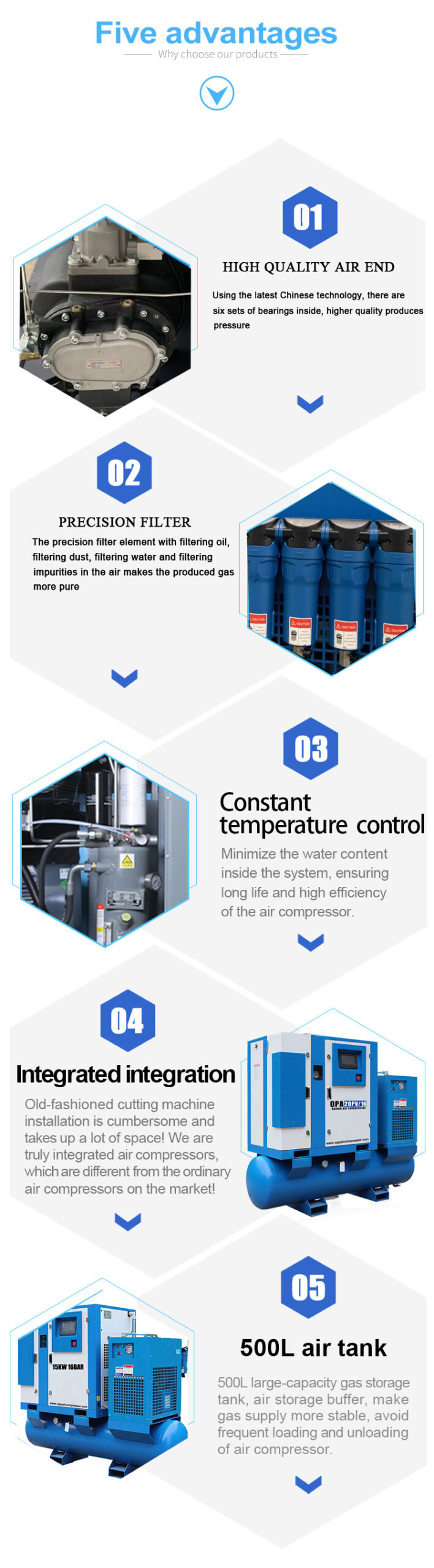

Pressure differentiation of integrated screw air compressor

1. High pressure series

(1) The appearance is integrated, with air tank and air dryer

(2) The pressure range is 16bar (232psi) -30bar (435psi)

(3) Divided into fixed speed and permanent magnet frequency conversion series

2. Ordinary pressure series

(1) The appearance is integrated, with air tank and air dryer

(2) The pressure range is 7bar (101.5psi) -12bar (174psi)

(3) Divided into fixed speed and permanent magnet frequency conversion series

Tank mounted with dryer and filter 16bar for laser cutting machine use

Screw air compressor–parameters:

| Model specification |

RMY-10AG | RMY-15AG | RMY-20AG | RMY-25AG | RMY-30AG | RMY-40AG |

| Exhaust volume Exhaust pressure M³/Min Mpa |

0.7/1.3 | 1.2/1.3 | 1.0/0.8 | 2.2/1.3 | 2.6/1.3 | 2.3/0.8 |

| 0.5/1.6 | 1.0/1.6 | 0.9/1.0 | 1.8/1.6 | 2.2/1.6 | 2.0/1.0 | |

| Power/ Horse power |

7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 |

| Exhaust temperature | ≤ Ambient temperature +8℃ | |||||

| Intake temperature | ≤ 45℃ | |||||

| Noise dB(A) | ≤ 68±2 | ≤ 70±2 | ||||

| Oil Content(ppm) | ≈2 | |||||

| L(mm) | 1670 | 1670 | 1670 | 2280 | 2280 | 2280 |

| W(mm) | 850 | 850 | 850 | 930 | 930 | 930 |

| H(mm) | 1570 | 1570 | 1570 | 1920 | 1920 | 1920 |

| Weight(KG) | 516 | 556 | 596 | 756 | 806 | 856 |

| Diameter of outlet | 3/4″ | 3/4″ | 3/4″ | 1″ | 1″ | 1″ |

Compressed air as auxiliary gas:

- For carbon steel plates, when compressed air is used as the auxiliary gas for cutting, the section of the part will generate relatively small burrs. The burrs are not sharp, and can be applied to parts that do not require high cutting surface.

- Stainless steel plate, compressed air is used as auxiliary gas. After the material is processed, the cutting surface will be oxidized. When the cutting section is welded, the oxide will produce slag and pores in the weld bead, which will affect the quality of the weld and cause the strength of the welded part to decrease. Therefore, if the compressed air is used as an auxiliary gas for cutting, and the parts need to be welded after cutting, the oxide layer of the welded part needs to be polished to improve the welding quality; in addition, the oxidation of the cutting surface will become a yellow oxide layer, When re-welding, the oxide layer needs to be polished.

- Aluminum plate and aluminum alloy plate, which uses compressed air as auxiliary gas, will reduce the cutting burr; if using nitrogen, the cutting burr will increase.

Laser cutting three auxiliary gases:

- Laser cutting machine uses different auxiliary gas to cut different materials. The thickness of the cutting material is not used, the pressure of the auxiliary gas and the required flow rate are different.

- There are three kinds of auxiliary gas for laser cutting machine, laser gas, compressed air, auxiliary gas

Laser gas: the gas used to generate laser in the laser generator

Compressed air: generally used to protect the optical path, can also be used as auxiliary gas

Auxiliary gas: gas ejected from the cutting nozzle of the cutting machine

- Oxygen for carbon steel cutting is generally required to have a purity of 99.5% or higher. The main function is to support combustion and blow off the cut melt. The pressure and flow rate vary according to the requirements of the cutting machine manufacturer. It is related to the size of the cutting nozzle model and the thickness density of the material. The general pressure requirement is 0.3Mpa-0.8Mpa, the flow rate is not fixed, such as cutting 22mm carbon steel, and some manufacturers require 10m3/h (including the use of oxygen (Protect double-sided cutting nozzle).

- Nitrogen is used for cutting stainless steel to prevent oxidation reaction and blow off the melt. The purity of nitrogen is particularly high (stainless steel with a thickness of more than 8mm, the purity must reach 99.999%), and the pressure is generally above 1.0Mpa. If you want to cut For stainless steel above 12mm or 25mm thickness, the pressure requirement will be 20Mpa or higher. The flow rate is determined according to the type of cutting nozzle. Generally 12mm thick stainless steel, the flow rate needs 150m3/h, and the thickness is 3mm stainless steel plate, the flow rate is 50m3/ h.

Permanent magnet Screw Air Compressors–16bar for laser cutting machine use

Stationary type–parameters

| Model No. | RM-10AM | RM-15AM | RM-20AM | RM-25AM | RM-30AM | RM-40AM |

| Air capacity (m3/min/Mpa) | 0.7/1.3 | 1.2/1.3 | 1.7/1.3 | 2.2/1.3 | 2.6/1.3 | 3.6/1.3 |

| 0.5/1.6 | 1.0/1.6 | 1.5/1.6 | 1.8/1.6 | 2.2/1.6 | 3.2/1.6 | |

| Power(KW/HP) | 7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 |

| Noise dB(A) | 68±2 | 70±2 | ||||

| Length (mm) | 900 | 900 | 900 | 1290 | 1290 | 1290 |

| Width (mm) | 850 | 850 | 850 | 900 | 900 | 900 |

| Height (mm) | 940 | 940 | 940 | 1190 | 1190 | 1190 |

| Weight (Kg) | 245 | 280 | 312 | 480 | 530 | 630 |

| Outlet size | 3/4″ | 3/4″ | 3/4″ | 1″ | 1″ | 1″ |

Air compressors can be grouped into three classifications: consumer grade, professional grade and industrial grade.

- Consumer grade air compressors can be described as a pancake or single-stage model. They’re used for household tasks like inflating tires and inflatable products and possibly some low-load air tools like staplers and brad guns.

- Professional grade air compressors provide more power and higher pressurized air. They could be two-stage reciprocating models or rotary screw models and can provide more power to run several air tools at once with intermittent use.

- Industrial grade air compressors will be the workhorse of a manufacturing plant or the reliable power source on an oil rig. They are designed to provide a steady flow of compressed air for long periods of time and can take fluctuating surges in use typical in major manufacturing plants. These compressors are built with high-quality components that allow for customization to the specific environment to improve performance, energy efficiency and reliability.

PLC controller functions of our screw air compresosr

Touch screen display shown

loading and unloading status

working hours

current pressure, temperature

full-load operation hours

filters and oil replacement time

running status

motor running status

main motor currency

electric current

cooling fan current

cooling fan operation status

Automatically alarm functions:

high temperature alarm

oil change-over time arrive alarm

air filter change-over time arrive alarm

pressure, temperature sensor fault alarm

oil filter change-over time arrive alarm

oil separator change-over time arrive alarm

communication fault alarm

belt extended use alarm(belt driven compressor)

Fixed Speed Belt driven screw air compressor for laser cutting machine–parameters:

| Model No. | RM-10AG | RM-15AG | RM-20AG | RM-25AG | RM-30AG | RM-40AG |

| Air capacity (m3/min/Mpa) | 0.7/1.3 | 1.2/1.3 | 1.7/1.3 | 2.2/1.3 | 2.6/1.3 | 3.6/1.3 |

| 0.5/1.6 | 1.0/1.6 | 1.5/1.6 | 1.8/1.6 | 2.2/1.6 | 3.2/1.6 | |

| Power(KW/HP) | 7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 |

| Noise dB(A) | 68±2 | 70±2 | ||||

| Length (mm) | 900 | 900 | 900 | 1290 | 1290 | 1290 |

| Width (mm) | 850 | 850 | 850 | 900 | 900 | 900 |

| Height(mm) | 940 | 940 | 940 | 1190 | 1190 | 1190 |

| Weight(Kg) | 230 | 262 | 292 | 450 | 500 | 600 |

| Outlet size | 3/4″ | 3/4″ | 3/4″ | 1″ | 1″ | 1″ |

- Special design for laser cutting machine

- 16bar high pressure customized for laser cutting industry

- High pressure,high efficiency cutting

AGKNX group is a world-class professional compressor manufacturer, established in 1986, with a history nearly 36 years. We have various types of air compressor. Please trust our profession. Quanwei give you best quality and service.

All in one integrated screw air compressor is one of our representatives.The scope of application is various,including:laser cutting,metal,frame processing,4S shop,chemical laboratories,etc…

If you need it but you don’t know how to choose,contact us directly. Looking forward to your consult.

Product Parameters

|

Model |

Screw air compressor for laser cutting QWQ-30ZB |

||||

|

Working Pressure |

bar |

12 |

16 |

||

|

Gas Displacement |

m³/min |

2.7 |

1.8

|

||

|

Noise Level/dB(A) |

68±2 |

||||

|

Motor Power |

kw/hp |

22/30 |

|||

|

Start Method |

Star Triangle Start |

||||

|

External Dimension(mm) |

L W H |

1350 850 1040 |

|||

|

Weight(KG) |

570 |

||||

|

Outlet Diameter |

G1″ |

||||

|

Certification |

CE/ISO9001 |

||||

|

Voltage |

380V/3PH/50HZ 220V/3PH/50HZ or as per your required |

||||

|

Remark |

We provide customized services. If you need, contact us directly. |

||||

Refrigerated Dryer

Easily filter out the moisture of compressed air.

Air Tank

Storage the air volume

Reduce the frequent times of air compressor

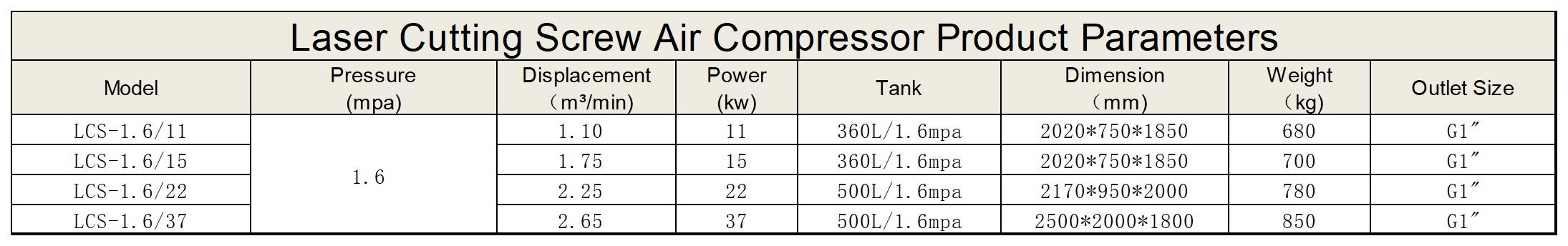

Screw Air Compressor for Laser Cutting

The combined screw air compressor integrates the parts including screw air compressor,

refrigerated air dryer, high efficient air filter and matched air tank, making is convenient for customers to install, use and move.

|

Product name

|

Screw Air Compressor for Laser Cutting

|

|

Model

|

LCS

|

|

Pressure

|

1.6MPa

|

|

Power

|

11/15/22/37 Kw

|

|

Capacity

|

1.1- 2.25m3/Min

|

|

Voltage

|

380V/50HZ, 220V/60HZ, 400V/50HZ, 415V/50HZ or Customer′s Requirements

|

|

Color

|

Customized

|

|

Screw Air Compressor for Laser Cutting

|

|

|

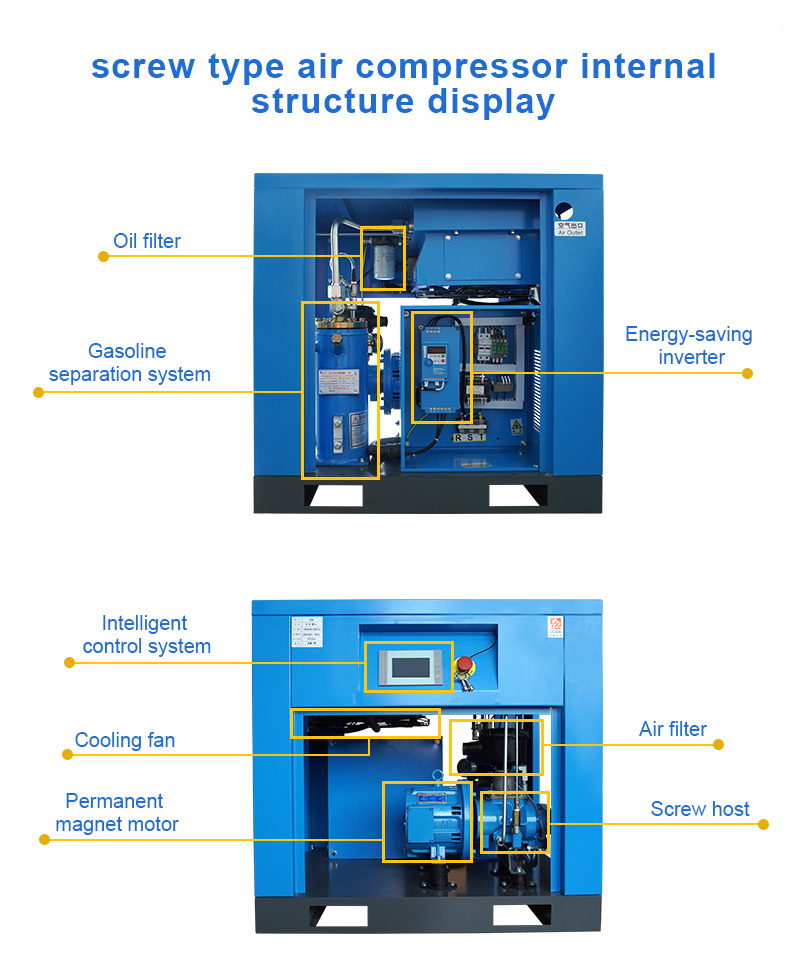

♦ Intelligent Touch-Screen Design

|

|

|

♦ Direct Driven

|

|

|

♦ Oil Gas Separator

|

|

|

♦ Oil Filter

|

|

|

♦ Air Filter

|

|

|

♦ Air Tank

|

|

|

♦ Piping Design

|

Advantages

Imported coupling, excellent material selection, wear resistance, anti-aging ability, elastic coupling, tight no clearance, no wrong tooth risk, plum blossom multi-head, 100000 high strength impact resistance tests to ensure stability and durability.

Control Panel

Real-time observation of the compressor operation status:Host, fans, exhaust gas temperature, exhaust pressure,power output, total electricityconsumption, fault messages, 24-hour customer service line.

Multifunction Design: Data curve, parameter settings,device information, data query.

Air Filter

High-quality filte,filter the dirts in the air reliably,dust particles can be controlled below 0.3 micron,filtering accuracy up to 99.99%.

1. Combined type screw air compressor is integrated with air compressor, air dryer, filters and air tank.

2. It’s easy to use. Users just need to connect it to the power supply for working.

3. It’s convenient for location movement with the 4wheels.

4. It’s cost effective, as there is no additional purchasing of the pipe for installation.

5. Air end of screw air compressor

The air end is with state-of-the art screw element and 4 -6 SKF bearings to make sure it plenty of air output and longer lifetime.

6.Electric Motor of the air compressor

Name brand qualified IP54 ,F insulation, IE2 , IE3 motor , high efficiency and energy saving.

7.Intake valve of the screw air compressor

High efficiency intake valve protects the compressor components by removing 99% dirty particles down to 3 microns.

8.Oil Air separator

High efficiency separating for oil and air and low oil content in the compressed air.

9.Touch Screen Controller.

|

No

|

Item

|

Data

|

|

1

|

Motor Power

|

11KW

|

|

2

|

Fan Power

|

0.45KW

|

|

3

|

Motor Rotating Speed

|

3000 rpm

|

|

4

|

Fan Rotating Speed

|

1440 rpm

|

|

5

|

Fan Air Volume

|

1.5m³/min

|

|

6

|

Cooling Method

|

Air-Cooled

|

|

7

|

Transfer Method

|

Direct Driven

|

|

8

|

Air Volume Adjustment Method

|

Frequency Conversion

|

|

9

|

Gas Oil Content

|

as little as 3 ppm

|

|

10

|

Safety Valve Set Pressure

|

Fixed Work Stress*1.2 MPa

|

|

11

|

Dimensions

|

1080*850*1200MM

|

|

12

|

Weight

|

344kg

|

|

13

|

Outlet Diameter

|

Rp1

|

|

14

|

Warranty

|

1 year

|

|

15

|

Package

|

Wooden Crate

|

Q1: Are you factory or Trade Company?

A1: We are factory of Hangzhou,Zhejiang. We have our own trade company for export.

Q2: How long is your product warranty?

A2: Usually the whole machine is guaranteed for one year

Q3: What voltage can you provide?

A3: We can support 220V/380V/400V/415V/440V, 50HZ/60HZ

Q4: How long is your delivery time?

A4: 1-10 sets, 380V/3P 50hz, we can delivery it between 7 days. Other voltage need be 7-15 days. More than 10 sets, need be 15-25 days.

Q5: How to pay?

A5: We support T/T wire transfer. Or delivery pay by Alibaba.

Q6: What should I do after maintenance?

A6: Our machines are easy to maintain and operate in the later stages. We support the sale of later maintenance parts, and later customers only need to operate according to our prompts. For inexperienced customers, we can provide video guidance.