Oil free air compressor

Air purity has always been the biggest concern for many applications; however, this miraculous oil-free air compressor has emerged as a great help to the applications that depend on pure air. As the name suggests the oil-free air compressor pump has no trace of oil present inside the compressor chamber, due to which the entire system does not come in direct contact with oil particles hence providing pure, uncontaminated air.

COMPANY INTRODUCTION & EVER-POWER

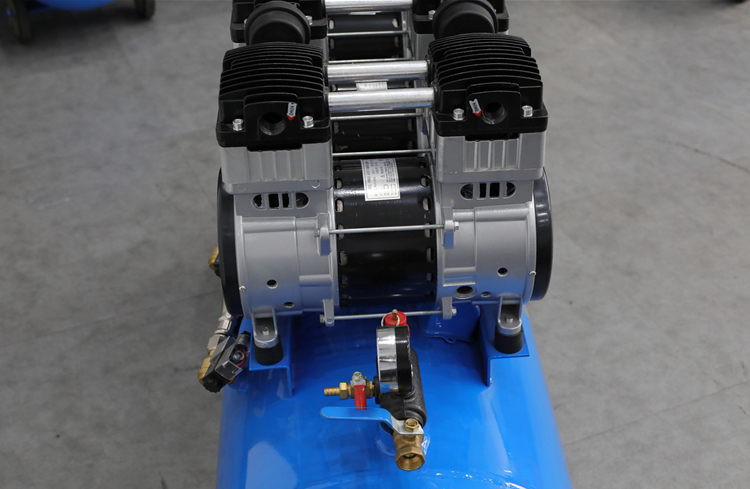

Oil Free Compressor

Variable frequency drive ( VFD) technology was used in oil-free air compressors since ages. Nowadays, the focus has been shifted to its production, efficiency and power conserving, however, they have become much more common for operating compressors of variable speeds. They can function many other works like- altering the speed, maximize production efficiency, optimize power problems, and slacken mechanical resources further they are used as a compressor controller or applied in the intersection with a proprietary air compressor controller.

Smart Pressure Gauge

Original Compressor Pump

Heavy-duty Crankcase

EP-SERIES VACUUM PUMP UNITS

Function

The oil-less air compressor starts functioning by drawing air through the valve and passing them through the air filters. The air filter is generally very fine and doesn’t allow any dust, dirt and small particles to enter the compressor. The unloader valve inside the compressor opens to pump air and place it into a loaded position.

Once the compressor is running, the air enters into the first chamber where it’s compressed and moves through the compressor to lower the temperature.

After the initial compression, the piston pushes the air through the intercooler, where the temperature of the air is lower down for further compression. However, there can be two cases, either the air can be used or sent to the second phase depending upon the nature of the compressor.

In the second phase, the air moves back to the main chamber of the compressor or second chamber (depending on the design) and is further compressed by high-pressure elements. After the second compression, the air again becomes very hot, so they are then sent to the aftercooler for cooling them down.

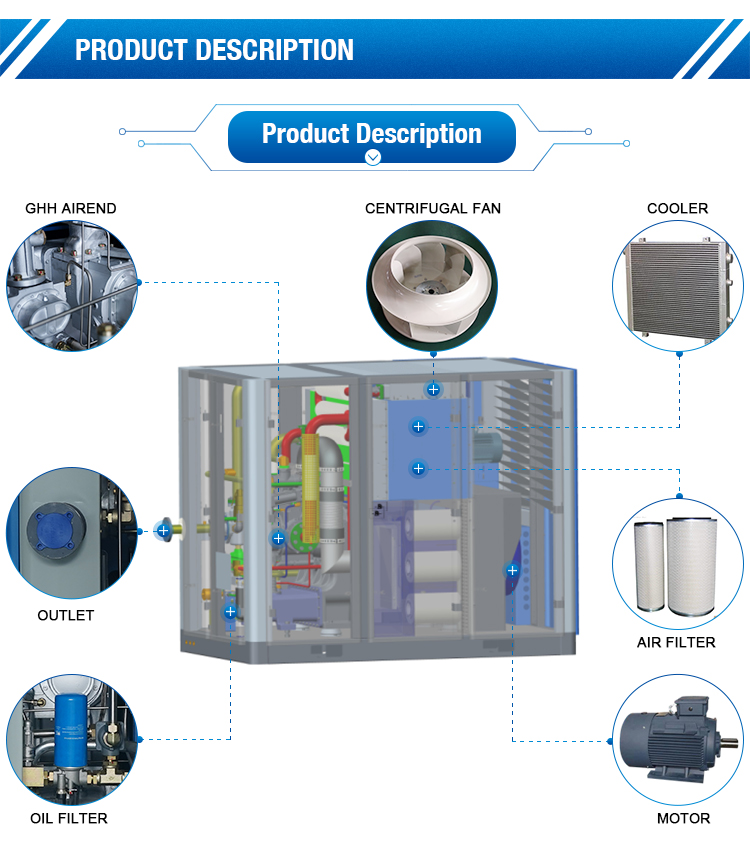

Oil-free silent screw for air compressor

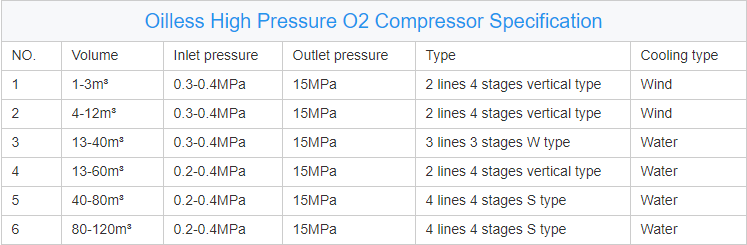

ring is self-lubricated material, all this guarantee oxygen is clean and no-pollution. Compressor working speed is slow, normally 200-400 rpm, to keep working do 24 hours heavy duty loading, this Oxygen compressor main use for hospital oxygen supplier center, to increase oxygen supply line pressure to the room, also can boost oxygen, and filling to the cylinder, such as 15Mpa, 20Mpa, also our oxygen booster, can use in Industrial acetylene cutting, cutting steel scrap in steel factory, support Boiler oxygen combustion recycle the cryogenic liquid oxygen tank vapor oxygen to the tank.

ChAll standard cylinder oxygen filling diaphragm compressor are CE marked to meet the requirements of the EU market. We can also provide customized plant filling oxygen compressor according to customer conditions. Our microboost medical oxygen compressor have the following features According to the different working conditions of the customer:

2. Oxygen for VPSA PSA and LOX gas source

3. NO pollution, keep the same purity into the gas

4.RELIABLE and high quality.

5. TOP low cost, low maintenance cost, simple operation, just change the piston ring

6. 4000 hours piston ring working life under low pressure conditions, 1500-200O hours working life under high pressure conditions

7. TOP brand motor, can be specially pointed out.

8. SUPPLY China market, china’s strict approval quality system

9. CE approved to meet the requirements of the EU market

10. According to the customer’s specific working conditions, the compressor is designed for single machine compression, two-stage compression, three-stage compression and four-stage compression.

11. Low speed, long life, average speed 260-350RPM,

12. Low noise, average noise below 75dB, can work quietly in the medical field

13. continuous continuous heavy-duty operation, can run stably for 24 hours without stopping

14. Each stage has an interstage safety valve. If the stage is overpressured, the safety valve will take off and release

the overpressure gas to ensure the stable operation of the compressor.

15. Each level has a temperature controller. If the temperature between the stages exceeds the standard, the temperature display will sound and light alarm.

Is an Oil-Free Compressor Really Better?

Oil-Lubricated Vs Oil-Free Air Compressors

Whether you’re a homeowner, contractor, or mechanic, at some point you’ve probably debated oil-lubricated vs. oil-free air compressors and wondered to yourself, “What’s the big difference?“

New information and technology seem to change every year, and while the ‘oil vs. oil-free’ question persists, the arguments don’t always keep up with these developments.

How Air Compressors are Lubricated

All compressors, regardless of their type, need a method of lubrication to moderate heat, friction, and the wear-down of the pump and critical components. The biggest difference, however, is whether the lube comes from oil or a special material coating.

Oil-Free Lubrication

Oilless compressors do not use oil for lubricating. Instead, their wearable parts are coated in special friction-reducing chemicals and are designed to be self-lubricating for the life of the compressor.

Is Oil or Oil-Free Better?

Now you know the basics of each type, we can now answer the question, “How does oil-free compare to oiled and which is better?” You’ve undoubtedly heard some myths, so let’s debunk them and explain what they mean to you, the user.

Myth #1: Oil Lubricated Compressors Last Longer

The chief argument these days is that oil-free compressors can’t match the longevity and dependability of oil lubed compressors and therefore don’t offer the same value. Routine maintenance and regular oiling tended to make oiled compressors more durable and have a longer lifespan than the first versions of oil-free machines. Although that might’ve been the case before oil-free technology took off, it just isn’t true anymore. Today’s oilless compressors run cooler and come better protected than ever before.

Myth #2: Oil-Free Compressors Are a Lot LOUDER

Again, the oil-free compressors of yesteryear were unquestionably loud, but today’s designs feature direct-drive, dual-piston (duplex) pumps and advanced sound-reducing technologies that make oilless compressors much softer than their oiled, shouty brethren.

Myth #3: Oil Lubed Compressors Run Cooler and Withstand Extreme Conditions

Actually, the dual-pump designs of oil-free compressors allow them to achieve the desired CFM/PSI in half the revolutions (RPM). They also use heat-dissipating aluminum cylinders to run cooler. In fact, oilless compressors are preferred in extreme cold because there’s no worry about the oil turning to sludge. On the other hand, oiled compressors may be desired if working in extreme heat and humidity, because they can dissipate heat more quickly in a given duty cycle and resist rust build-up.

Advantages/Disadvantages of Both

Oiled Compressors

An industry-standard among professionals, oiled stationary compressors are typically installed in a shop where high pressure and volume keep all of the tools running all day, every day and stand up to years of abuse if properly maintained.

- Suited to professional applications

- Higher RPMs mean higher PSI/CFM ratings

- Heavier, not as portable

- Requires routine maintenance

- Can be used in hot climates

- Oil contaminates the air

Oil-Free Compressors

These types of pumps (duplex) operate at lower RPM, reducing the noise, heat, and friction which extends the pump’s life cycle and, mixed with better castings/exacting tolerances and better frictionless coatings, make oil-free a great choice in many applications.

- Cleaner, drier air

- Lighter weight, more portable

- Maintenance free, no oiling needed

- No oil filters required

- Can be used in cold weather

- Quieter, more efficient

Achieve your goals

Company Concept

Company adhering to the management objective of quality first, prestige supreme.

Strong Technical Force

Strong technical force, superior to similar products in Japan and Germany, please refer to oil free compressors in China comparison for more detailed information. Advanced production and testing equipment, strict implementation of ISO9001 quality management system, products have obtained CE certification, and the ep series have passed US authoritative testing and certification

24/7 Customer Support

24×7 service support is one of the best services in the company. 24×7 service support providing quality services at anytime, anywhere in the world.

Top benefits of using an oil-free air compressor

Contrary to traditional compressors, oil-free ones can operate in more than one direction. With their size and weight being smaller, they are easily transportable without any leakage issues while tilting them. Besides, unlike the old style of compressor that is bulky with a ton of cords hanging out everywhere from it, these new types are very easy and have sleek designs.

Instant start

Oils are more viscous and sluggish in cold temperatures, but oil-free compressors don’t suffer from this limitation. Because of this difference, an oil compressor takes longer to start up when the temperature drops below a certain point while you’re working – it’s just harder for the oil-lubed compressor to get going with their gooey oils at lower temperatures. Whereas oil-free models can start quickly no matter what!

Environmental friendly

Eliminating oil from the air compressor helps to keep the environment safe because this type of compressor does not release contaminants into the air. In addition, certain tasks might require clean and oil-free air such as – food industry, pharmaceutical industry, paper industry, etc. Therefore, one cannot encounter any form of contamination or damage due to an oily substance like these compressors provide that peace of mind.

Besides benefiting the environment the oil-free air compressor reduces the cost which makes them budget-friendly as well.

Our range of Compressors

- Screw compressor

- Scroll compressor

- Oil-free compressor

- Oilless compressor

If you need to know more information about our oil-free compressor, then feel free to start a conversation with our experts, you can just leave an email to get in contact with us at [email protected]

To check our inventory visit us on

Ready to get started?

Keep in touch or order products