Oil-less compressor

The oil-less compressor is a more efficient and environmentally friendly alternative to obtain pure vacuum. Due to the absence of oil during the operation, this air compressor option has emerged as a great choice for places that employ the use of fresh, pure, hygienic and clean air.

COMPANY INTRODUCTION & EVER-POWER

Oiless Compressor

The machine is light, easy to carry.

Without refueling in use process, low energy consumption, simple maintenance and low cost

The machine little vibration, low noise

Compared with similar machines, the air charging time is faster and the work is reliable.

Suitable for food, medical treatment, woodworking decoration, scientific research institutions, and compressed gas as a power source in the field.

Oilless Compressor Suppliers in China | China Oilless Compressors

Energy saving: energy saving more than 15% compared with dry oilless compressors in China.

Environment protection: no using any lubricate oil to avoid environment pollution.

Reliability: absolutely guarantee oil less.

Because the purified water takes part into the compressing process to seal, cool and lubricate, it increases efficiency. With the same motor power, comparing with dry oil less air compress, there is 15% more air production of oillesscompressor of water lubrication, it reduces the energy consumption greatly. The consumption material of oil less screw air compressor is only water, air filter and water filter, the maintenance cost is very low.

100% oil less compressed air, 100% purified compressed air, 100% no oil pollution risk.

In the process of food and drink industry, medical industry, packing industry, electronic manufacture, painting industry, powder coating industry and textile manufacturing, it must avoid any risk of oil pollution, otherwise it would cause serious consequences such as manufacture damages and stop, brand and credit losing. oil less screw air compressor takes water for lubrication, there is not any lubricate oil in the air end, and at the meantime, because the purified water clean the air, the compressor air is absolutely clear and not any pollution.

Oilless Air Compressor with Advanced Technologies

Advantages of using an Oilless compressors in China

Energy saving

Oil-less compressors have several advantages, but water lubrication is one of the best and most effective ones. When the purified water takes part in the compressing process to seal, cool and lubricate, it increases efficiency. With the same motor power compared with a dry oil-less air compressor there’s 15% more air production because it’s compressed by less air pressure in comparison (about 1/6th). This makes them easy on electric bills too. Resulting in saving more energy than the oil-lube compressors. And since there is no trace of oil, it is also safe for the environment.

Besides, the consumption material for an oilless screw compressor only consists of Water; Air filters; Warming up tools which are just used when needed during wintertime as they consume lots of energy thus it’s not necessary to provide it throughout the whole year.

Eliminate the risk of pollution

When it comes to oil and food industries, medical industry, packing industry or electronic manufacturing companies- any risk of them being polluted is not an option. If they are then the consequences can be serious such as injuries in production and stops due to damages; also brands may suffer from a decrease in credit which will lead to high losses overall. The use of water for lubrication by air compressors instead creates fewer risks than with oils does because there would otherwise be an increased danger if left unchecked.

In the process of food and drink industrialization, electronics manufacture (such as cellphones), packaging processing or other businesses that need lubricant around their machinery – have no chance at all when it comes down to protecting against possible threats brought on by pollution.

Oiless Silent Air Compressor

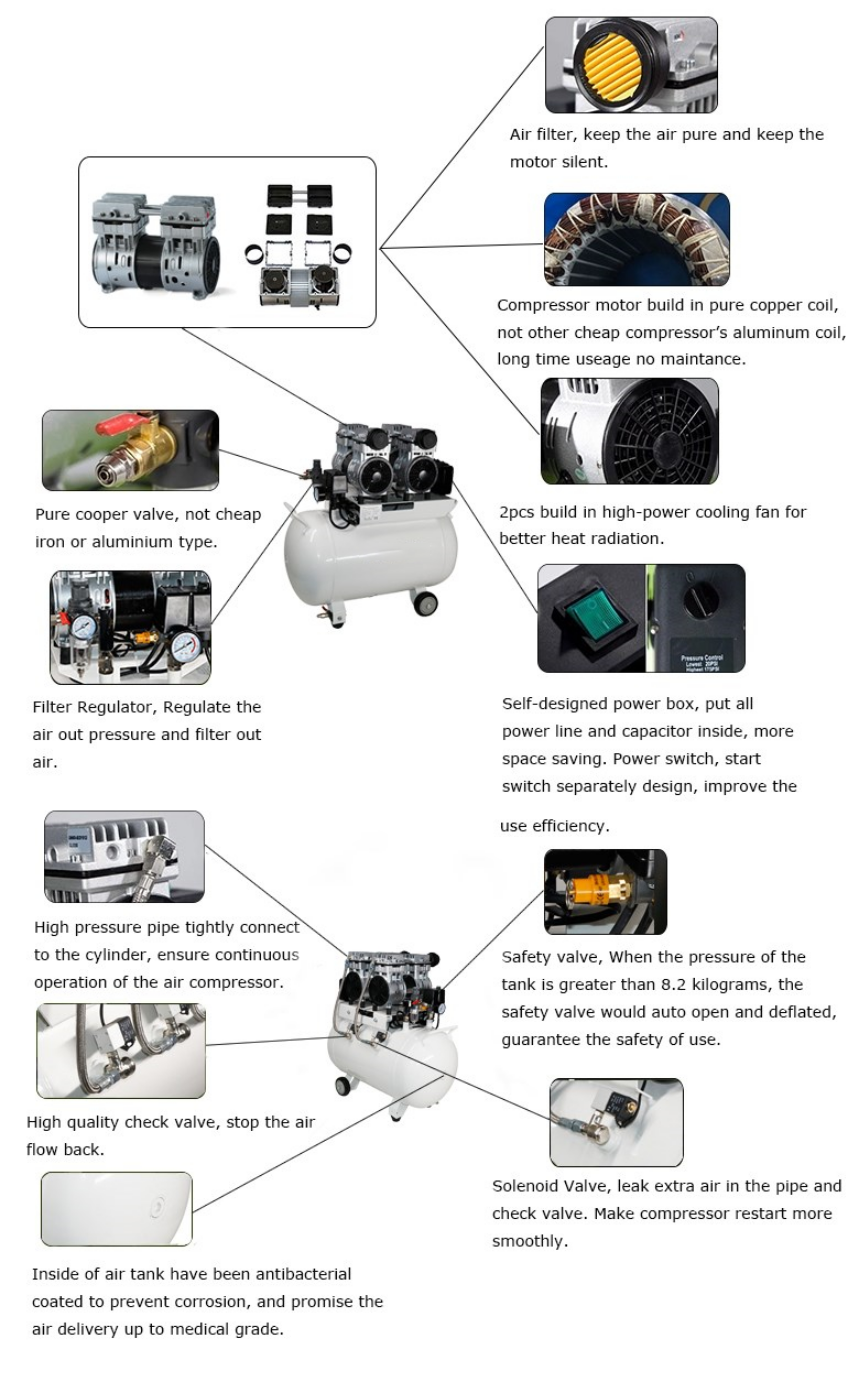

1. 100% oil free air certified by Germany TUV.

2. Centrifugal Fan for better cooling effect.

3. Stainless Steel Pipe.

4. Hydraulic Inlet Valve System.

5. Special venturi tube design to help reduce the noise down.

6. Double-layer structure to reduce he noise.

7. Air Cooling and Water cooling are available.

8. VSD control are available.

9.Touch Screen PLC with preset running schedule, more intelligent control.

Leading Technology:

The durability of EP two stage compression airend uses high performance rotors and durable bearings to ensure reliability. Stainless steel seals and the unique design of the labyrinth seals mean that this unique design is time tested, reliable and efficient.

Dry Oiless Technology:

Since the launch of the EP oil free airend thousands have been produced and are in use worldwide. Typically oil free air is used in processes such as pharmaceutical, food and beverage, and electron-ic industries where high quality air is required.

Stainless Steel Rotors:

EP pioneered the use of stainless steel rotors to ensure longevity and reliability.

Oil Free Airend – UltraCoat TM Super Coating:

The surfaces of the oiless airend are coated with UltraCoat, a special coating which improves efficiency and extends the life of the stainless steel rotors. The strong coating adhesion and high tempera-ture resistance ensures that there is no reduction in performance with age.

How Do Oiless Air Compressors Work?

Compressed air is only as good as its purity. When your process is exposed to oil, it becomes increasingly difficult to keep air clean, increasing the costs you’ll face — especially as you use more and more air. To address this concern, many companies are turning to oiless or oil-less air compressors. Today, oiless compressors are becoming more common because they offer cost savings.

These purity and environmental benefits will often translate into other savings that may reduce your overall ownership costs. Here are a few of the things to consider if you’ve been wondering: “How do oiless air compressors work?”

- There’s no need to collect or dispose of oil-ladened condensate.

- Downstream filters have reduced replacement needs, because they’re not filtering oil.

- Energy costs are minimized because there’s no need to increase force — some fluid-flooded units can see a downstream pressure drop due to filtration.

- Reduced oil costs, because there’s no need to continually refill your compressor.

- Typically, these units can unload within two seconds of the command to unload, and will use about 18% of their full load horsepower when unloaded.

Those savings can be very tempting. To see if you can make use of the oil-less compressors, you’ll need an understanding of how the compressors work and in which applications they work best.

Contact Us Learn More Find A Dealer Near You

Functional Steps of How Oiless Air Compressors Work

Understanding how oiless air compressors work and why they last as long as they do is best illustrated by reviewing each function in a step-by-step method. Let’s walk through how an oil-less air compressor starts working and provides you with the compressed air that you need.

1. Drawing in Air

Oil-less air compressors start by bringing in outside air through their unloader valve and passing it through an inlet air filter (or filters) in order to ensure that the air is clean. The filter will limit damage to your compressor and its internal components. These filters are typically fine enough that they keep out dust, dirt and small debris.

The unloader valve opens to help the compressor pump air into its chamber, placing it in the “loaded” position. When the valve closes, the compressor enters the “unloaded” condition and begins running. When your compressor is running and actively delivering compressed air, it typically won’t be able to draw in any more air.

When you turn on your compressor and it starts to draw in air through an open unloader valve, the first destination for the air is the low-pressure compressor element.

2. First Compressor Element

You’ve probably noticed that your air compressor can create heat, and this often has to do with the low-pressure compressor element, because it’s working without any oil.

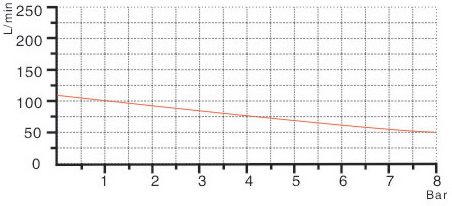

The average compressor element will operate at around 2.5 bar, and compressing air alone can make the unit operate at a temperature of up to 180 degrees. That can be more than twice as high as the temperature that oil-lubricated compressors reach, due to the lack of a flowing medium that whisks away heat.

Oiless elements will begin compressing the air and then move it through your compressor to cool the air down so it can be used in your applications.

3. Intercooler Access

After it’s initially compressed, pistons will push the air through an intercooler, where the air can cool so it can be further compressed. This will either move it to the second phase of compression or the final one, depending on the nature of your compressor.

Compressing air generates heat that limits the oxygen content of the air, thus reducing its density. Cooling the air essentially acts as a simple method for allowing denser and more oxygen-rich air to be again used by the engine, which in turn provides more fuel and improves the power output when the air compressor is working with a combustion engine.

Intercoolers are essential for two reasons. First, they cool the air down to a proper temperature to minimize the risk of any damage related to heat. Second, intercoolers allow air to be compressed at much higher PSI’s in two-stage pumps, and the cooling process means the second stage will face less wear.

Cooling air can lead to some condensation, and intercoolers will come with standard filters designed to remove moisture and water from the air. You’ll typically see this filter listed as a moisture trap.

After the air is cooled, it’s returned to your compressor for additional compressing.

4. Second, Higher-Pressure Compression

The air will move back into the main chamber of your air compressor — or the second chamber, depending on its design — and will be further compressed by a high-pressure element. The maximum pressure you’ll achieve typically ranges from 116 to 145 psig.

The air again becomes very hot due to the lack of lubrication in the surrounding elements, so it will need to be cooled once more.

5. Air Prep and Aftercooler Access

During its second phase of compression, the air will reach temperatures of around 150 degrees, requiring additional cooling before it can be used in other equipment. The aftercooler is the destination for air after its final compression stages, and this cooling allows it to be properly stored.

As air flows to the aftercooler, it will pass through a check valve that is designed to prevent any backflow, ensuring that air continues to compress and fill your tank. Backflow will damage your equipment and cause a major failure of the air compressor.

Many compressors — especially reciprocating compressors — are fitted with pulsation dampeners, and these are located just before the aftercooler. The dampener is designed to reduce pulsations and vibrations caused by the air compressor when it uses suction and opens discharge valves.

Pulsations can reverberate through the piping system, and these vibrations will make it difficult for your tools and machinery to measure air pressure and use it properly.

The air is finally stored or sent to your equipment for use.

6. Pressure Switches

Detection equipment in your air compressor tank will monitor the level of air you have. When it falls below a specified level, the air compressor will turn back on and start working to rebuild the pressurized air in the tank. The pressure switch is what is used to monitor and turn the compressor off and on.

- Pressure switches are typically attached to the unloader valve, though sometimes the valve is internal.

- Pressure switches are set by the factory and arrive at predefined levels.

Achieve your goals

Company Concept

Company adhering to the management objective of quality first, prestige supreme.

Strong Technical Force

Strong technical force, superior to similar products in Japan and Germany, please refer to vacuum pump comparison for more detailed information. Advanced production and testing equipment, strict implementation of ISO9001 quality management system, products have obtained CE certification, and the ep series have passed US authoritative testing and certification

24/7 Customer Support

24×7 service support is one of the best services in the company. 24×7 service support providing quality services at anytime, anywhere in the world.

Benefits of Oiless Compressors

100% PureAir

If 100% clean and oiless compressed air is a requirement for your industry, you cannot compromise on quality. Our oiless compressors are capable of providing the atmosphere essential for clean air applications. We set the standards for air purity and are ISO 8573-1 CLASS 0 certified. These oil-less compressors offer 100% pure oil‑free air and improve energy efficiency.

Increased Sustainability

With 100% contaminant-free air, we are confident that your compressed air system will run as clean and efficient as possible.

Lower Maintenance Cost & Energy Savings

A true oiless compressor does not have oil in the compression chamber. This minimizes downstream filtration requirements and pressure drops, which directly translates into energy savings and a lower total cost of ownership.

Zero Risk of Contamination

Some processes need clean, dry, oiless air that cannot risk contamination. With an oiless compressor, you get peace of mind in your system and your business.

These two are the major benefits that often translate into other savings and contribute to reducing the total cost of ownership.

- With the oil-less air compressor, there is no need to collect and dispose of oil-landed residue.

- Since it eliminates the need for constantly refilling the compressor with oil, this helps to reduce the total cost of fuels.

- Generally, the unit unloads within two seconds of command and uses about 18% of its full load horsepower when unleaded.

- The total cost of energy and requirements are reduced, and because the oil-less operation doesn’t need the high force and filtration, some fluid flooded units can also notice a downstream pressure drop.

- The system doesn’t employ oil that eliminates the need to filter the oil through the filters for functioning which further reduces the requirement to change the downstream filters.

For every industrial work which requires a pure, hygienic vacuum then the oil-less system is certainly the best option. Besides providing a clean vacuum they are also suitable because of their size.

Our range of Compressors

- Screw compressor

- Scroll compressor

- Oil-free compressor

- Oilless compressor

To buy these amazing oil-less air compressors visit us https://roots-vacuum-pump.com/vacuum-pumps/

If you want to know more about compressors and other equipment then contact us at [email protected]

and we will be available to solve your queries.

Ready to get started?

Keep in touch or order products