Scroll Compreor

Ein Kompressor ist ein Maschinenteil in Ihrem Klimagerät, das gasförmiges Kältemittel verdichtet, damit es durch die Kühlschlange strömen und in Ihr Haus geleitet werden kann, um die Luft zu kühlen. Ein Scroll-Kompressor ist eine besondere Art von Kompressor, der durch rotierende Metallteile funktioniert, anstatt wie ein Kolben in einem Motor.

Warum ist ein Scroll-Kompressor besser? Was macht AGKNX als die beste Scroll-Luftkompressor Lieferanten in China?

Scroll-Kompressoren haben weniger bewegliche Teile, was sie energieeffizienter, leiser und weniger störungsanfällig macht. Für den Hausbesitzer bedeutet dies in der Regel eine bessere Erfahrung, da das System weniger Betriebs- und Reparaturkosten verursacht und weniger Lärm erzeugt als ein herkömmlicher Kompressor.

UNTERNEHMENSVORSTELLUNG

Scroll-Verdichter

Agknx ist ein erfahrener Hersteller und Vertreiber von Scroll-Pumpen, die in der ganzen Welt eingesetzt werden. Mit unserem Engagement für die Bereitstellung von Qualitätsprodukten, die die Bedürfnisse der Kunden erfüllen, haben wir industrielle Gadgets bereitgestellt, die Ihre Investition wert sind.

Scrollverdichter werden seit Jahren in der Kältetechnik eingesetzt. Durch den Einsatz von fortschrittlicher Technologie und neuem Design hat Agknx ein völlig modernes Produkt auf den Markt gebracht. Mit dem patentierten W-Scroll-Verdichter ist unsere Technologie weitaus effizienter und zuverlässiger als die traditionellen Hubkolbenverdichter.

dVorteile:

1. Neue Generation hocheffizienter Druckluftanlagen

5. Hochleistungs-Frequenzumrichter

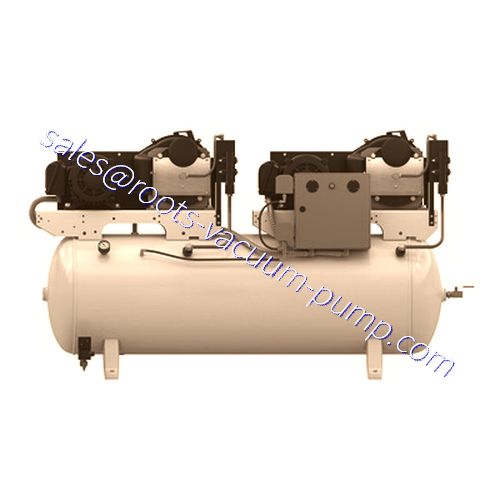

300cfm Luftbürste Luftkompressor 10 bar 55kw Scroll-Schraubenkompressor

Unsere Scroll-Kompressoren sind für alle Arten von industriellen Anwendungen geeignet

Der von uns entwickelte Scroll-Kompressor arbeitet mit zwei Spiralen, von denen eine stationär ist und die andere umläuft, um mechanische Energie zu erzeugen. Daher eignen sich die Kompressoren für den Einsatz in vielen verschiedenen Industriezweigen, wie z. B. in der Lebensmittelverarbeitung, in Brauereien, Chemieanlagen und Erdgaspipelines.

Wir bieten einen Scroll-Kompressor, der hohen Temperaturen standhalten kann

Die Forscher und Konstrukteure von Agknx haben die Scroll-Kompressoren neu konzipiert und sie zu einer effektiven Lösung für die Kühlung Ihres Unternehmens bei minimaler Lärmbelästigung gemacht. Die neu entwickelten Produkte können auch bei höheren Temperaturen arbeiten als andere Verdichtertypen, was bedeutet, dass sie perfekt für industrielle Umgebungen geeignet sind, in denen große Hitze üblich ist. Mit unseren Scroll-Kompressoren läuft Ihr Unternehmen also immer reibungslos, egal was Sie ihm zumuten.

Ölfreie Scroll-Luftkompressor-Systeme

Innovatives Multiplex-Design, das es ermöglicht, genau die Anzahl von Kompressoren zu betreiben, die Ihrem Bedarf entspricht, und das mit einem effizienten Teillastbetrieb.

Nahezu geräuschloser Betrieb mit der leisesten Kompressionstechnologie und weniger beweglichen Teilen für geringere Vibrationen und eine gesunde Arbeitsumgebung.

Weniger Komponenten und weniger Verbrauchsmaterialien für höhere Zuverlässigkeit, was zu einer längeren Lebensdauer, weniger Wartung und längeren Wartungsintervallen führt.

Geringerer Platzbedarf mit einem kompakten Kompressor und einem Nachkühler, der eine ausreichende Kühlung mit einer geringen Temperaturdifferenz (CTD) bietet, um den Platzbedarf der Luftaufbereitungsanlage zu reduzieren.

Kühler Betrieb mit dem integrierten Radiallüfter, der eine eingebaute Ladeluftkühlung erzeugt, ohne dass ein zusätzlicher Hilfslüfter für einen zuverlässigen Betrieb erforderlich ist.

THE BENEFITS OF SCROLL TECHNOLOGY

High quality, energy efficient compressor choices

85% fewer moving parts over hermetic compressors, significantly reducing failure

9-24% reduction in energy consumption, lowering costs

Enhanced performance & durability over hermetic compressors

When efficiency, quiet operation, low maintenance and a small footprint are critical, Scroll Air Compressors are the smart choice. Their compact and innovative design make them ideal for many commercial applications where reliable oil-free air is required. Our Scroll Compressors deliver more flow per kW in most cases and reach pressures up to 145 psi in a single stage of compression with no metal to metal contact anywhere – therefore the technology requires no lubrication resulting in high quality oil-free air.

Efficiency. Durability. Performance. Reliability

Two proven choices for supply chain continuity

Approved for new high glide refrigerants: R-407A/C, R-448A, R-449A

Easy “drop-in” replacement on both models

Standard two year warranty on EP scroll models

Standard one year warranty on Copeland scroll models

Extended warranty available for both models

Excellent “after-sale” support from dedicated representatives

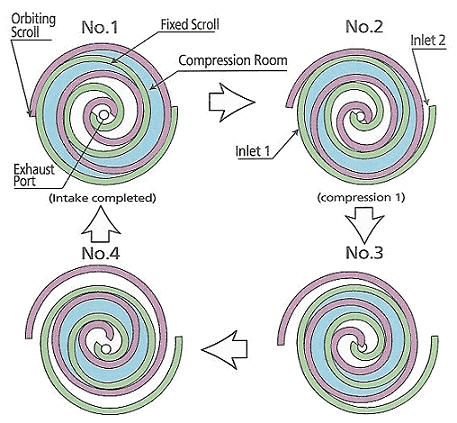

How a scroll compressors work

A scroll compressor actually consists of two scrolls or spirals. One scroll is moving, whereas the second one is fixed (attached to the compressor body). The first scroll orbits (rotates) in a path defined by its mating fixed scroll. The orbiting scroll is connected to the compressor’s crankshaft.As a result of the scroll’s movement, gas pockets are formed between the two scrolls. At the outer part of the scrolls, the pockets suck in gas and then move towards the center of the scroll, where the compressed gas is discharged. As the gas moves into the continuously smaller internal pockets, both its temperature and pressure are increased. Thus a desirable discharge pressure is achieved by the motion of the compressor scrolls.

Figure 1 – Diagram showing how a scroll compressor works

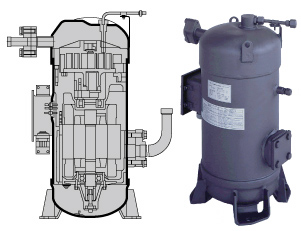

Structure of a scroll type compressor

Scroll compressors are fully hermetic (enclosed in the compressor’s shell, which is usually a cylindrical welded steel shell). Majority of scroll compressors used in refrigeration and HVAC services are of vertical orientation, with the scroll sets typically installed on the upper part of the motor shaft.

Figure 2 – Typical scroll compressor diagram

Using valves in a scroll compressor

Normally, suction or discharge valves are not used in these compressors. But dynamic discharge valves are preferred at the compressor discharge, when operating at high differential pressure values. In such scenarios, having a dynamic valve at the discharge increased the efficiency of operating the compressor. For example, scroll compressors operate at high differential pressure, in case of refrigeration applications. In such cases dynamic discharge valves are preferred.

But in other cases, for example – air conditioning, having a discharge valve actually results in pressure losses, reducing the efficiency. Hence these are normally not preferred.

Advantages

Scroll type compressors are inherently more efficient compared to other types of compressors for many reasons:

- The absence of pistons for gas compression enables scroll compressors to reach 100% volumetric efficiency, leading to reduced energy costs.

- Re-expansion losses, a typical feature of each piston stroke encountered in reciprocating models, are eliminated. In addition, valve (ports) losses are eliminated, since suction and discharge valves (ports) do not exist.

- Furthermore, due to the absence of several moving parts, scroll compressors are considerably quieter in operation compared to other types of compressors, like for example reciprocating type ones. Scroll compressors typically make 5 to 15 dBA lower noise than other compressor types.

- Due to lower vibration and noise, they do not need spring suspensions.

- Fewer moving parts, lower vibrations and less friction also means that these compressors are more durable.

- Their weight and footprint are considerably smaller compared to other bulkier types of compressors in use nowadays.

- Gas pulsation is also minimized, if not eliminated and consequently, they can operate with less vibration.

Disadvantages

- Being fully hermetic, perhaps the biggest disadvantage of scroll compressors is that they are generally not easily repairable. They cannot be disassembled for maintenance.

- Many reciprocating compressors are tolerant on rotating in both directions. This is usually not the case for scroll compressors.

- Incremental capacity control on systems with several scroll compressors has proven several times to be problematic as well.

Applications

Since their introduction, scroll compressors have been successfully used in applications involving food and fruit refrigeration, truck transportation, vacuum pumps, marine containers as well as residential and small to medium scale commercial air-conditioning applications.

Selecting a scroll compressor

When selecting a compressor you can either go for single phase or 3-phase motor for the compressor. It will completely depend on what kind of electricity connection is available. Normally, single phase connections are available. If 3 phase connection is available, then the three phase motor is considerably more efficient.

Next, you should consider the differential pressure and flowrate parameters. There are different scroll compressors available in the market, having different combinations of differential pressure and flowrate values. You should select the one which covers your requirements of certain minimum differential pressure at given flow rate.

Next, you can look at secondary parameters like the noise level etc. depending upon where the compressor is going to be used. If it is going to be used in a residential air conditioner, you will prefer to use a model with lower noise levels.

Technical parameters for CMW series Oil-free scroll air compressor

| Modell | Motor power | Working pressure | FAD | Noise | Connection | N.W. | Dimension | |

| L*W*H | ||||||||

| KW | HP | Mpa | L/min | dB(A) | inch | kg | mm | |

| CMW2.2-0.8 | 2.2 | 3 | 0.2-0.8 | 255 | 49±3 | 1/2″ | 132 | 670*630*945 |

| CMW3.7-0.8 | 3.7 | 5 | 0.2-0.8 | 415 | 52±3 | 1/2″ | 150 | 720*680*1050 |

| CMW4.4-0.8 | 2.2*2 | 6 | 0.2-0.8 | 510 | 52±3 | 1/2″ | 150 | 800*650*1020 |

| CMW7.4-0.8 | 3.7*2 | 10 | 0.2-0.8 | 830 | 55±3 | 1″ | 185 | 880*720*1120 |

| CMW11-0.8 | 3.7*3 | 15 | 0.2-0.8 | 1245 | 58±3 | 1″ | 300 | 1450*900*1150 |

| CMW15-0.8 | 3.7*4 | 20 | 0.2-0.8 | 1660 | 61±3 | 1″ | 350 | 1450*900*1150 |

| CMW2.2-1.0 | 2.2 | 3 | 0.2-1.0 | 215 | 49±3 | 1/2″ | 132 | 670*630*945 |

| CMW4.5-1.0 | 4.5 | 6 | 0.2-1.0 | 410 | 52±3 | 1/2″ | 150 | 720*680*1050 |

| CMW4.4-1.0 | 2.2*2 | 6 | 0.2-1.0 | 430 | 52±3 | 1/2″ | 150 | 800*650*1020 |

| CMW9-1.0 | 4.5*2 | 12 | 0.2-1.0 | 820 | 58±3 | 1″ | 185 | 880*720*1120 |

| CMW13.5-1.0 | 4.5*3 | 18 | 0.2-1.0 | 1230 | 61±3 | 1″ | 300 | 1450*900*1150 |

| CMW18-1.0 | 4.5*4 | 25 | 0.2-1.0 | 1640 | 61±3 | 1″ | 350 | 1450*900*1150 |

| CMW3.0-1.2 | 3 | 5 | 0.2-1.2 | 210 | 49±3 | 1/2″ | 135 | 670*630*945 |

| CMW4.2-1.2 | 4.5 | 6 | 0.2-1.2 | 360 | 52±3 | 1/2″ | 150 | 720*680*1050 |

| CMW6.0-1.2 | 3*2 | 8 | 0.2-1.2 | 420 | 52±3 | 1/2″ | 150 | 800*650*1020 |

| CMW9-1.2 | 4.5*2 | 12 | 0.2-1.2 | 720 | 58±3 | 1″ | 185 | 880*720*1120 |

| CMW13.5-1.2 | 4.5*3 | 18 | 0.2-1.2 | 1080 | 61±3 | 1″ | 300 | 1450*900*1150 |

| CMW18-1.2 | 4.5*4 | 25 | 0.2-1.2 | 1440 | 61±3 | 1″ | 350 | 1450*900*1150 |

Achieve your goals

Company Concept

Company adhering to the management objective of quality first, prestige supreme.

Strong Technical Force

Strong technical force, superior to similar products in Japan and Germany, please refer to vacuum pump comparison for more detailed information. Advanced production and testing equipment, strict implementation of ISO9001 quality management system, products have obtained CE certification, and the ep series have passed US authoritative testing and certification

24/7 Customer Support

24×7 service support is one of the best services in the company. 24×7 service support providing quality services at anytime, anywhere in the world.

More versatile

The scroll compressors we produce can be used for both low-temperature and high-temperature applications, making them an excellent choice for many different industries. They can also work with a wide range of fluids, including water, oil, air or gas. This makes them versatile enough to meet your needs no matter what they may be.

Reliable and lasting

The compressor we deliver is reliable and will last years without breaking down. Moreover, keeping up the quality is our topmost priority and to maintain we offer top-notch products at competitive prices.

Features of our oil-free scroll air compressor

- The robust motor can provide high-quality work.

- The high precision and proficient design can serve for a longer time.

- Improved compressor efficiency due to the use of permanent magnet motor.

- Smooth functioning, minimum vibration and noise.

- The motor is directly connected with air-end

- It doesn’t require extra adjustments

- PLC controller display discharge temperature, operation time, pressure, fault alarm, maintenance remain time, etc

Our range of products also includes:

- Rotary piston pump

- Air-cooled root vacuum pump

- Scroll compressor

- Screw compressor

- Rotary vane pump

- Oil-free compressor

- Oilless compressor

- Gebläse

- Water band vacuum pump

- Liquid ring vacuum pump

- Reciprocating vacuum pump

- Vacuum valve and others

If you desire to be at the forefront of this revolutionary new technology, then, Agknx is your best bet. We offer a wide variety of models that will not only suit any application but also your budget. Even if you lack knowledge and information then don’t worry! We put together the pages with all the information you may need and our specialists are always there to guide you in finding the perfect fit for your application.

To reach us an email at [email protected] Find more about us by visiting our website https://roots-vacuum-pump.com/vacuum-pumps/

Applications