Liquid Ring Vacuum Pump

Through our unremitting efforts in innovation and product development, we continue to introduce high-quality Liquid Ring Vacuum Pumps in China and product upgrades that can meet the strict requirements of the most demanding applications while reducing the total cost of ownership. Discover the best EP liquid ring vacuum pump for your process.

COMPANY INTRODUCTION & EVER-POWER

Zhejiang EVER-POWER Vacuum Equipment Manufacturing Co., Ltd. is located in Wubei Town, which is known as the “Hometown of Pumps and Valves in China”. We-vacuum pump manufacturers and vacuum pump distributors-specialize in the production of vacuum pumps with extensive experience in this field. Through the dedication and hard work of our young team, our products enjoy a high reputation at home and abroad. Our main products include rotary vane vacuum pumps…

Liquid Ring Vacuum Pumps

Liquid ring vacuum pump

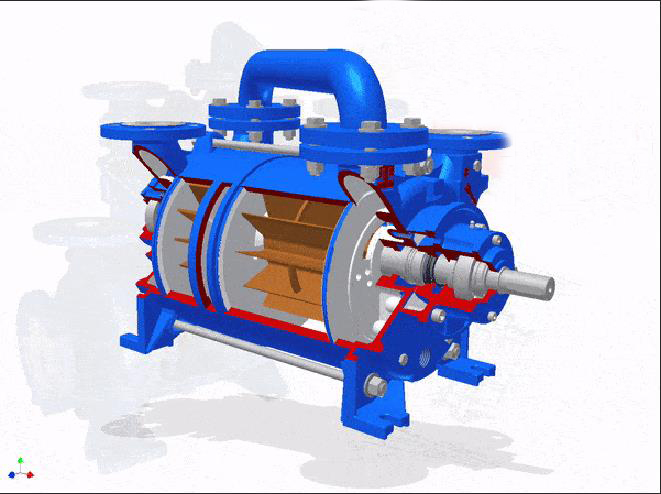

The liquid ring vacuum pump is a compact, high-performance machine that works on the principle of positive displacement and mechanical laws to provide industrial processes. It’s essentially an air compressor that creates a partial vacuum by compressing and cooling down gases until they condense into liquid form before releasing them back to their original volume. Furthermore, these machines are mainly employed for process vacuums where very little or no atmospheric pressure is required.

When the blades on an impeller cell are moving deeper into the liquid ring, they increase their pressure to release the discharged water through a port. The pump uses water sealant in liquid ring vacuum pumps which is also a safe and reliable choice for handling dirty gas streams. Additionally, this simple process has no contact parts which makes it easy to operate with one hand on top.

Liquid Ring Vacuum Pumps

They are typically used as a vacuum pump, but can also be used as a gas compressor. The function of a liquid-ring pump is similar to a rotary vane pump, with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression-chamber seal. They are an inherently low-friction design, with the rotor being the only moving part. Sliding friction is limited to the shaft seals. Liquid-ring pumps are typically powered by an induction motor.

| Applications

|

Industries

|

Working mechanism

The liquid ring vacuum pump consists of a multi-blade impeller which is positioned eccentrically in the cylindrical chamber, where the liquid is drawn.

As the shaft starts rotating the liquid present in the chamber creates a liquid ring by the centrifugal force that is generated by the rotating impeller. Due to the continuous force, the liquid ring is held tightly against the inner wall of the chamber. The systematic arrangement of the impeller and pumping chamber causes inconsistency of the blades because it enters the liquid ring at different depths depending on how they are angled. This in and out of blades creates an increase in cell volume on the inlet port side, producing a vacuum.

The steady flow of fresh sealing liquid is supplied to the pump through the sealing-liquid inlet.

Proven Performance

Reliable Liquid Ring Technology

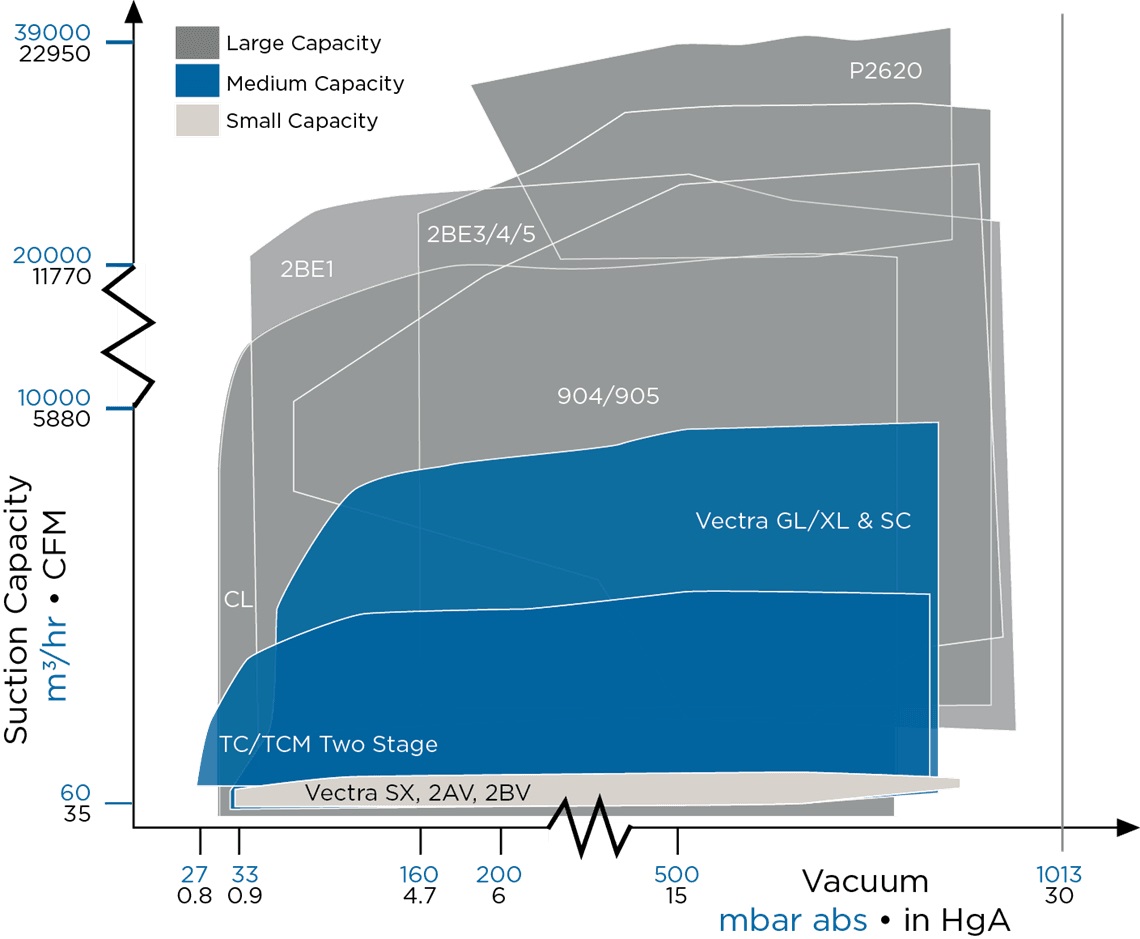

The working principle of a liquid ring pump is based around a pump body and an eccentric rotor. As the rotor spins, the seal liquid inside the pump forms a rotating “liquid ring” on the inner surface of the body. NASH liquid ring vacuum pumps feature three product sizes including small capacity, medium capacity, and large capacity liquid ring pumps.

Small Capacity Pumps

(Vacuum levels up to 29in. HgA, 1.5 HP to 10 HP)

NASH small capacity liquid ring vacuum pumps feature monoblock or lantern designs. These designs deliver the benefits of a simple, compact, and economical installation. Our small capacity liquid ring pumps are available in a variety of materials including cast iron and stainless steel and are ideal for use in a vast range of general industrial processes.

Click the link below to learn more about our small capacity liquid ring vacuum pumps.

Medium Capacity Pumps

(Vacuum levels up to 28in. HgA, 10 HP to 200 HP)

NASH medium capacity liquid ring vacuum pumps offer a highly powerful range of small to medium size single stage vacuum pumps for use in diverse industries including oil & gas, general industrial, and chemical.

Available in cast iron for less aggressive applications, and stainless steel for hostile applications and environments.

Click the link below to learn more about our medium capacity liquid ring vacuum pumps.

Large Capacity Pumps

(Vacuum levels up to 25in. HgA, above 200 HP)

NASH medium to large capacity single stage vacuum pumps are ideal for demanding applications in extremely tough conditions. These heavy-duty pumps are able to serve a wide range of applications, which can typically include dewatering in the paper industry and vacuum filtering in mineral ore processing. Our large capacity pumps are available in a variety of materials including stainless steel, cast iron with some models featuring a polyisoprene lining.

Click the link below to learn more about our large capacity liquid ring vacuum pump.

Large Capacity Pumps

(Vacuum levels up to 25in. HgA, above 200 HP)

NASH medium to large capacity single stage vacuum pumps are ideal for demanding applications in extremely tough conditions. These heavy-duty pumps are able to serve a wide range of applications, which can typically include dewatering in the paper industry and vacuum filtering in mineral ore processing. Our large capacity pumps are available in a variety of materials including stainless steel, cast iron with some models featuring a polyisoprene lining.

Click the link below to learn more about our large capacity liquid ring vacuum pump.

Characteristics Of Liquid Ring Vacuum Pumps

- Accepts Carryover – Soft solids, moisture, slugs, chemicals, and more will not harm the pump but are washed out through the pump discharge.

- Cool & Quiet Operation – The pump runs cool due to the circulation of the sealing water inside the pump.

- Continuous Operation for Any Process – The pump can operate constantly and continuously at any vacuum level up to 1in. HgA.

- Easy Maintenance and Longer Pump Life – Our pump only has one moving part so there is less wear and simple maintenance, making our pumps more affordable.

- Environmentally Safe – Our pumps do not require oil changes, filters, oil-pans, condensers, etc. so operating facilities run clean and free of any oil contamination and discharge.

Highest Standards

Nash is committed to the highest standards in production and safety. We have many ISO certificates, issued to our facilities worldwide and continue to improve our quality by optimizing internal processes.

Achieve your goals

Company Concept

Company adhering to the management objective of quality first, prestige supreme.

Strong Technical Force

Strong technical force, superior to similar products in Japan and Germany, please refer to vacuum pump comparison for more detailed information. Advanced production and testing equipment, strict implementation of ISO9001 quality management system, products have obtained CE certification, and the ep series have passed US authoritative testing and certification

24/7 Customer Support

24×7 service support is one of the best services in the company. 24×7 service support providing quality services at anytime, anywhere in the world.

Plug and play modules

We take the hassle out of selecting your vacuum system. All AW liquid ring pumps are offered as pre-engineered plug and play modules, suitable for operation in once through, partial recirculation or total recovery mode. With the benefits of liquid ring technology whilst saving water and saving energy you get a liquid ring module that works for you.

Engineered systems to suit your needs

For more complex requirements, our project team is here to develop a unique engineered system tailored to suit your needs. Our liquid ring pumps form the backbone of multistage systems in materials of your choice to the specifications you need. With the help of our vacuum engineers, the possibilities are endless.

Tailor-made solutions

For more complex projects, the Atlas Copco applications teams develop systems tailored to meet the unique requirements of any customer. Atlas Copco experts can offer liquid ring packages adapted to most process conditions, including special materials and design of multi-stage systems.

Advantages of liquid ring vacuum pump

Environment friendly

Liquid ring vacuum pumps are a great option for hazardous jobs, as they don’t have any hard contact parts. The safe sealant is also environmentally friendly and can be chosen from many options to suit your needs

Quiet operation

The pump circulates water to maintain a cool operation. Due to this, it is quieter than other pumps.

Constant operation

The perfect vacuum for any occasion. The pump is apt for operating constantly and continuously at any atmospheric pressure.

Easy to Maintain & extended pump life

When a liquid ring vacuum pump system is used to create the perfect airtight environment, it can be much simpler and more cost-effective than other traditional methods. The only moving part in this model of pump is mounted firmly on a shaft that’s supported by bearings designed for long service life as well as continuous operation; these attributes benefit users with less wear and easier maintenance costs.

So if your job requires the use of a safe and hygiene vacuum then Liquid Ring Vacuum Pumps in China are a great option. To buy a highly productive, reliable and efficient liquid ring vacuum and pump and other equipment contact us at [email protected]

You can also visit our website to check out more products and learn more about us https://roots-vacuum-pump.com/vacuum-pumps/

Ready to get started?

Keep in touch or order products